3D PRINTING UK

3D Printing Blog | News | Reviews | Shop

-

-

3D Belt Printers – What Are They For?

-

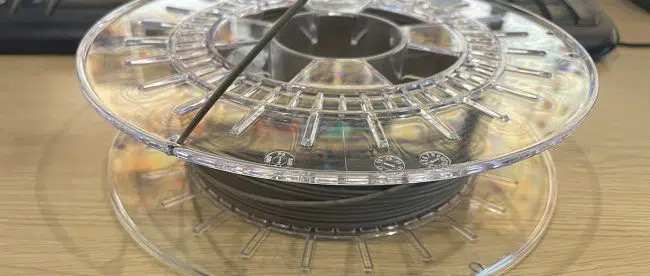

Review – PrimaSelect Metal Filament

-

Is 3D Printing The Future Of Recycling?

-

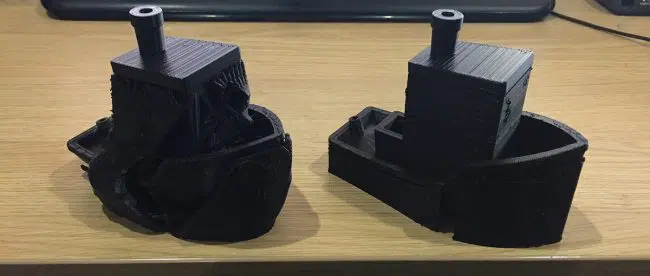

Tree Supports – Are They Really Better?

-

More Things I’ve 3D Printed!

-

Ender 3 Extruder Upgrade

-

Printer Review – Flashforge Finder

-

Review – Creality Direct Drive Upgrade Kit for the Ender 3

LATEST POSTS

-

1st December 2023 0

Why nitrogen is essential for your Dental 3D Printing curing oven

The popularity of 3D printing in the dental industry has been expanding, and along with it the [MORE] -

2nd June 2023 0

How Is Our Ender 5 S1 Doing?

As all our regular readers will know, we got our hands on a Creality Ender 5 S1 a couple of months [MORE] -

26th May 2023 0

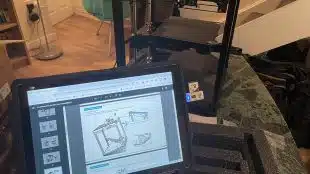

Review – Creality Slicer

We take a good look at Creality's new slicer and see how it compares to Cura. [MORE]

3D PRINTING NEWS

-

3rd December 2019 0

3D Printed Guns – Are They A Problem?

The Liberator is a single-shot 3D printed gun made up of sixteen parts, mainly using ABS filament. [MORE] -

20th November 2020 0

Black Friday 3D Printer Deals!

Are you looking for some superb Black Friday 3D printer deals? We have them in here! [MORE] -

1st January 2020 0

A year in 3D printing – 2019

We take a look back at what happened in the world of 3D printing during 2019. [MORE]

REVIEWS

-

1st May 2023 0

Creality Ender 5 S1 – Review

Here we do a nice detailed review of the new Creality Ender 5 S1 3D printer. [MORE] -

2nd December 2019 0

Formlabs Form 2 – Professional printer review

The Formlabs Form 2 professional printer is expensive, but you only get what you pay for. [MORE] -

25th December 2021 0

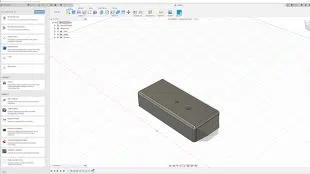

Design Software – Autodesk Fusion 360

The Autodesk Fusion 360 interface is very different from FreeCAD, but it has a lot of options. [MORE]

ENDER 3 CUSTOM BUILD PROJECT

-

15th April 2021 0

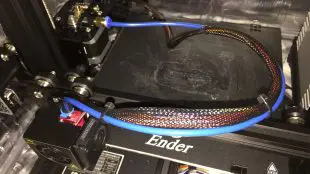

Upgrading A Bowden Tube

Replacing the Bowden tube is a very cheap and effective upgrade you can do on your own 3D printer. [MORE] -

22nd February 2021 0

Blog Update – Where We’re Going From Here

Fergus has a quick update on what you can expect from 3D Printing UK for the rest of 2021. [MORE] -

26th September 2021 0

3D Printer Troubleshooting Special

Our recent print project failed on us about 15 minutes before it was due to finish, so we did some troubleshooting. [MORE]

SCIENCE

23rd November 2019

1

Scientist uses 3D printing to recreate trilobites

Dr Allan Drummond, an assistant professor of biochemistry at the University of Chicago, likes trilobites. [MORE]

3D PRINTERS

11th October 2022

0

What Have I Been 3D Printing?

Fergus shows us what he has been 3D printing lately in this blog post. [MORE]

-

31st May 2021

-

14th November 2020

-

19th February 2020

-

1st January 2020

POPULAR

2nd August 2021

2

What Am I 3D Printing This Month?

Fergus shows us a very nice selection of very useful objects that he has 3D printed over the last couple of months. [MORE]

-

23rd November 2019

-

23rd November 2019

3D PRINTING UK RUNNING MH PURITY