Tree Supports – Are They Really Better?

3D printer supports interest me. When you’re using an FDM 3D printer, supports are something you need to keep in mind because, sometimes, you’re definitely going to need them. A while ago I looked at whether we need quite so many as we tend to use (probably not) but there are times when you just can’t avoid it.

If you do need supports there are a couple of options open to you. I slice with Cura and that defaults to the traditional style of support, but it also has the option of “tree” supports. These are a lot more organic-looking than the usual squared-off blocks under any overhanging bits, and the idea is that they have less contact with the surface of your print as well as being easier to remove. I’ve used both kinds of supports. In fact I tend to switch between them reasonably often, usually because whatever one I’ve been using has annoyed me and I decide that of course the other one is much better.

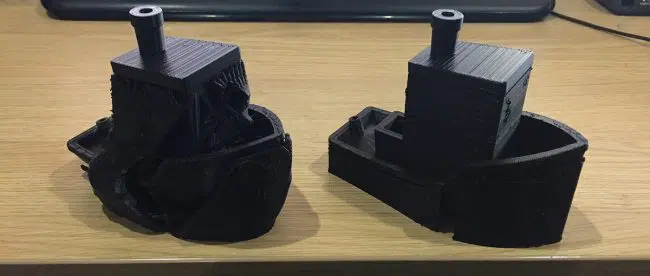

Anyway, I decided it was time to actually test both types of support and see if one of them really is better. As this is a test of 3D printer performance the obvious thing to do was to run off a couple of Benchies, but honestly, I’ve already printed multiple Benchies with both tree and traditional linear supports, so that seemed sort of boring. Then I had an idea. What about printing a couple of big Benchies?

These are really quite big.

Printing a big Benchy is easy: Just open the file in Cura then change the scale to 200%. This will immediately turn the familiar tiny tugboat into a fairly substantial piece of plastic. I sliced this twice – once with standard supports, and once with tree supports. Then I spent a day and a half printing these monster Benchies. With that done, it was time to start evaluating the two styles of supports.

Economy

One of the annoying things about supports is that you’re 3D printing something that you then break off and throw in the bin. That’s a waste of time, filament and energy, so you want to minimise the amount of support material you’re printing. One of the selling points of tree supports is that they use less material – but it turns out that’s not the case, at least with a Benchy.

According to Cura, one of my giant Benchies with no supports would use 63g of filament and take eight hours 33 minutes to print. With standard supports that goes up dramatically, to 95g and 13 hours 56 minutes. Tree supports, on the other hand, come in at 99g and 15 hours 28 minutes. Some rough maths tells me that tree supports are also slower to print, probably because of their more complex shape. For standard supports the extra time works out at 10.1 minutes per gramme; for tree supports it was 11.5 minutes per gramme.

So tree supports are, in this case at least, slower and more expensive – but there’s not a huge amount in it.

Ease of Removal

Your 3D printer will put the supports on for you, but getting them off the finished print is up to you – and it can be a pain in the rear.

Well, there was a huge difference here. The tree supports snapped off very easily; in fact, a couple of smaller bits came off while I was removing the print from the bed, and the rest were just as easily removed. Even allowing for some digging inside the wheelhouse with a knife, it took me less than ten minutes to remove all the tree supports from Big Benchy #1.

The standard supports were a very different story. Getting rid of those took well over an hour, and involved lots of hacking, gouging and wrenching with pliers. One problem with standard supports on a Benchy is that the entire wheelhouse is surrounded in support material, to hold up the edge of the roof. You need to carve a hole in that through one of the doors, then peel it away from the outside with pliers. After that you can shove the pliers in the front and back windows to start breaking loose the mass of support material inside the wheelhouse. Eventually it will all tear loose and come out in a tattered lump, but before that happens you spend a long time pulling out little scraps.

Tree supports are much easier to remove. No contest whatsoever.

Print Quality

Finally, we need to consider 3D print quality. After all there’s no point in having easily removed supports if the object you remove them from is horrible. Does the style of support actually make any difference here?

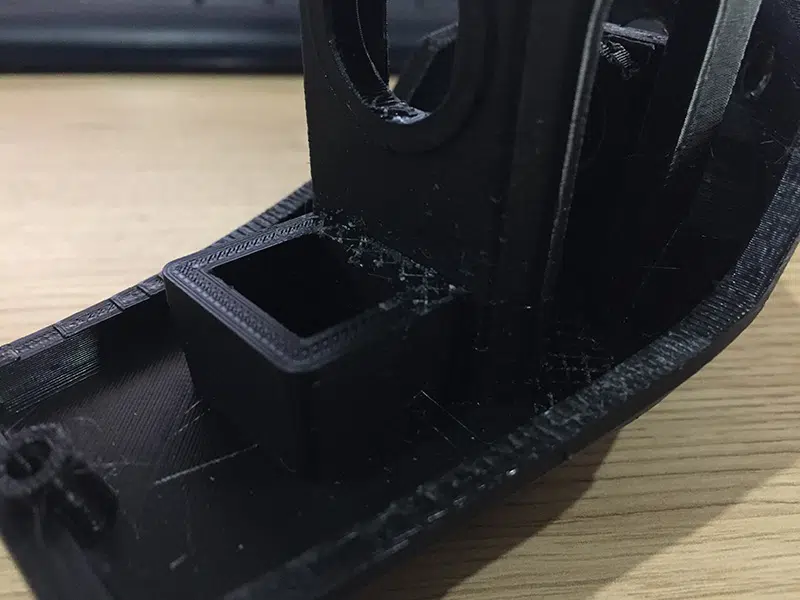

There are definitely some rough spots here.

In theory, it shouldn’t affect the actual print at all, because the supports are separate. If there’s any difference you’d expect tree supports to edge it because, generally, they make less contact with the print and are easier to get off. So imagine my surprise when I found a slight, but noticeable, superiority in the quality of Big Benchy #2 – the one with standard supports. The supports were a lot harder to remove, but when they finally did come off they did so more cleanly. Of course this was somewhat balanced out by the couple of gouges I put in one side of the wheelhouse trying to lever its support blanket off with a knife…

The Verdict

Overall, I’d say tree supports win by a slight margin, mainly because they’re so much easier to remove. They’re best when you can select the option of only attaching them to the 3D printer’s bed, though; if any supports are growing from the object itself you might be better off with the standard variety.

Leave a comment

You must be logged in to post a comment.