Upgrading A Bowden Tube

If you’re a regular reader of this blog you’ll know that a couple of weeks ago I was having some filament feed issues with our Ender 3. I spent a couple of days poking and prodding the thing, but the problem turned out to be moisture in the filament rather than any issue with the printer itself.

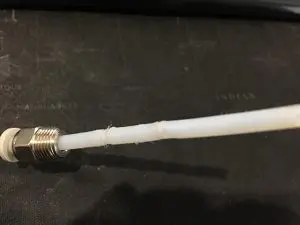

This is not a happy tube

Nevertheless, in the process I did discover an issue with the printer: The Bowden tube that carries filament from the extruder to the hot end wasn’t holding up too well. The plastic had developed a noticeable bulge around where it locks into the coupling, and while I don’t think that was a major cause of the feed issues I really doubt it helped, either. So I got on ebay and looked for a replacement Bowden tube, and to my pleasant surprise a 50cm PTFE tube, complete with new couplings, only costs £4.79. So I bought one.

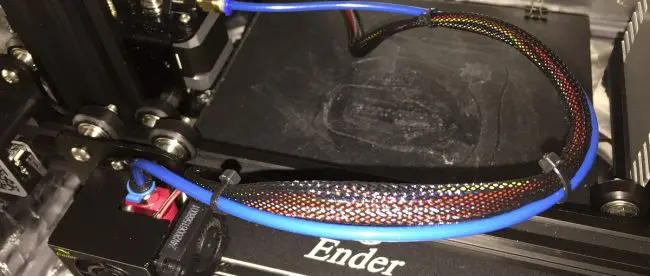

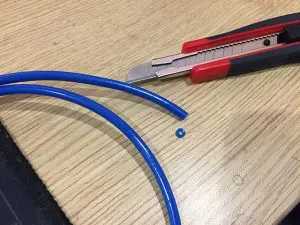

The original tube that came with the Ender 3 is a semi-translucent white, which means you can see the filament inside it. The new one is blue and very much not translucent, but on the plus side it’s thicker and feels more substantial. It also feels much slicker, which should mean less friction on the filament.

Is This Complicated?

Carefully cut the cable ties that fasten the old tube to the cable, then unlock the couplings and pull the tube out (if you can). Remove the couplings from extruder and hot end, and fit the new ones. Then push the tube into the couplings and use the clips to lock it in place. Get a few small cable ties and secure the new tube to the cable. Be careful not to over-tighten the cable ties. They just need to be tight enough to hold tube and cable together; any tighter and they can start to crush the tube, which will cause feed issues.

Does It Work?

I fitted the new tube two days ago, and the printer has been running flawlessly since then. The old one was in a pretty deplorable state where it fitted into the hot end. It still worked, but the new tubing feels like much higher quality. It also seems to give smoother feeding, which after all is what it’s there for, so I’d say this is a cheap and simple upgrade.

In the longer term we’ll probably change to direct drive, which will eliminate the Bowden tube altogether. Of course the extra weight of the extruder on the beam can cause its own issues, so adding a second threaded rod to power the other end of it might be necessary. Stay tuned for more Ender upgrades!

Leave a comment

You must be logged in to post a comment.