Top Tips For Your New 3D Printer

If you got a 3D printer for Christmas, the chances are you’ve already encountered some of the more common issues that can affect them. We love additive manufacturing; a 3D printer isn’t just fun to experiment and tinker with, it’s a great addition to your household toolkit. I’ve mentioned before how, when I need some small widget around the house, I now tend to reach for FreeCAD instead of my hammer and screwdriver. 3D printers are brilliant – but they can also be infuriating and temperamental. Here’s how to deal with some of the most common frustrations.

Nothing To Print?

If your 3D printer is working fine, but you’re bored with the handful of models preloaded onto its TF card, the easiest way to find new projects is to check out Thingiverse. This site has thousands of ready-made 3D models you can download, slice and print – and they’re free.

If you want to design your own prints, but you’re not sure how to start, download a copy of FreeCAD. As the name suggests it won’t cost you anything, and although it looks intimidating it’s not actually all that hard to start designing your own 3D objects. We have quite a few articles on the subject, including the absolute basics if you just want to get started.

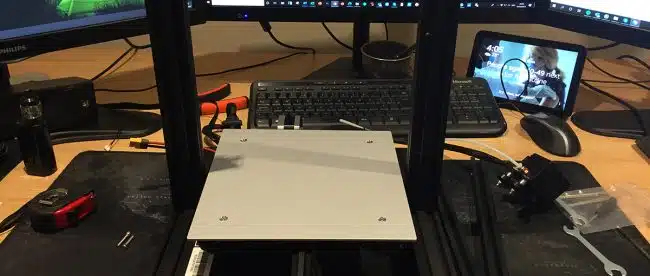

Wandering Projects?

One of the most common issues with 3D printing is having your half-printed project suddenly come unstuck from the print bed. When this happens you’re going to have to start again – and if you don’t catch it quickly you’ll also have to clear up a tangled bird’s nest of filament that the printer has continued to squiggle out. So how can you keep your projects firmly stuck down?

The first thing to do is level your print bed. This is something you should do regularly anyway, unless your printer has a self-levelling system – and if it doesn’t, you should seriously consider fitting one.

If the bed is level and things are still coming unstuck, the solution is to make your bed stickier. My favourite solution to this is a can of 3D LAC, but some people swear by Pritt Stik, hairspray – the cheaper the better, apparently – or a neatly applied layer of blue painter’s tape.

Poor Print Quality

If your prints started off nice and neat, but the quality is going down, your filament is starting to break more often and your extruder is making a suspicious clicking sound, it’s likely your filament is getting damp. Yes, it’s plastic, but many filament materials can still absorb moisture from the air; once they’re inside the printer’s hot end that moisture will evaporate and the filament will swell. If it swells enough the extruder won’t be able to feed it into the nozzle smoothly, and your prints will start to look like woodworm have been at them. Damp filament also becomes brittle and more likely to break, which will also lead to a failed print unless you have a break sensor.

Don’t worry, though – damp filament (PLA and nylon are particularly prone to soaking up moisture, by the way) can be salvaged. You can buy dehumidifying filament storage boxes, but they’re expensive – too expensive if you have a collection of different filament types. I have a kitchen dehydrator and if a roll of filament starts to suffer from moisture I simply dry it out in that for a few hours; otherwise heat the oven to about 50° and put the filament in it on a clean wire rack for a couple of hours. Once it’s dry, put it in a sealed bag or container. I vacuum-seal mine with a sachet of dessicant gel.

Are you having any issues with your 3D printer that aren’t covered here? Leave a comment and we’ll get back to you with a solution!

Leave a comment

You must be logged in to post a comment.