Keeping Your 3D Printer Well Maintained

Our Ender 3 has been running for close to a year now, and apart from a few glitches caused by damp filament or upgrade attempts I’ve been impressed at how reliably it’s kept chugging away. One reason it’s performed so well, I suspect, is that I try to give it regular maintenance.

I’ve looked at maintenance before, but that was a while ago. Now that I have some hands-on experience of living with a 3D printer I thought it was about time I revisited the subject, so here’s what I’ve picked up since the Ender first whirred into life last year.

Cleaning 3D Printers

As great as they are, 3D printers are messy things. The Ender 3 seems to generate an incredible amount of plastic debris; the lower frame is always liberally dusted with strands and particles of PTFE. On top of that there’s glue residue from when I give the print bed a quick scrape between jobs, and while the enclosure does a great job of keeping out normal household dust and hair there’s always a little bit that somehow sneaks in.

Every week, give your printer a quick once-over with a brush and duster. If you have a small vacuum cleaner – I have a mini one that I originally bought to get cat hairs out of my keyboard – that will do a good job of cleaning out the channels on the frame, which are natural places for assorted debris to collect.

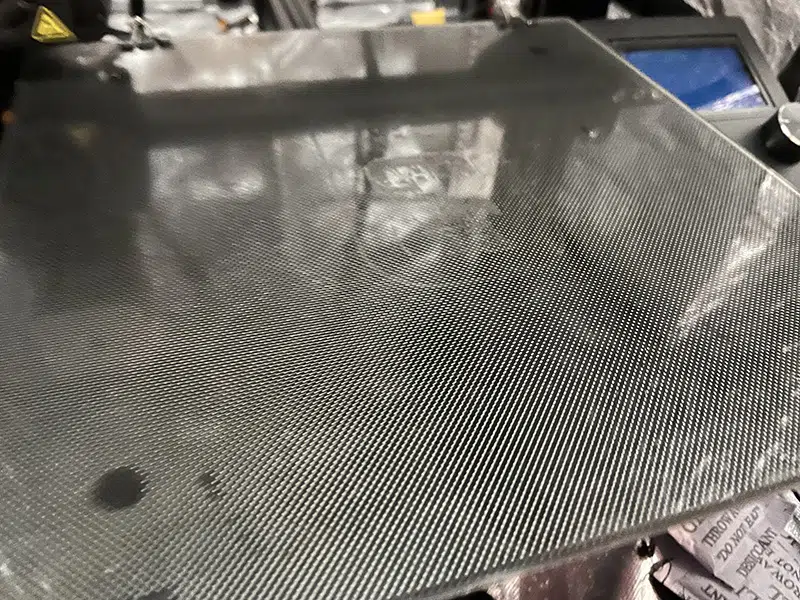

Pay attention to the print bed. Normal handling and use will deposit dust, plastic, glue and fingerprint oil on the surface; over time these will cause adhesion problems and warping. Glass beds can be cleaned with hot water, washing-up liquid and a kitchen sponge; other types will come up nice and clean after a rub down with a cloth and isopropyl alcohol.

This bed could do with a clean.

What To Lubricate

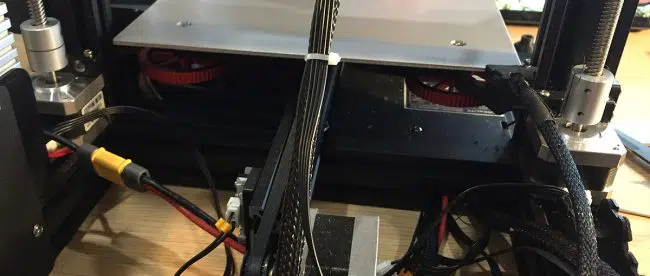

There isn’t actually a lot on a 3D printer that needs lubrication, but what does need lubricated is critical – the Z axis lead screws. If the print head sticks or binds on the screws as it’s raised you’ll get poor-quality prints, and possibly complete failures, so the screws need to be clean and lubricated.

The problem with lubrication is that while a nice coat of oil or grease will work great at first, it will soon attract dust – or particles of plastic, of course. You have two ways to get around that. One is to wipe the screws clean every week, then relubricate them with white lithium grease (or shredder oil, if you’re tight-fisted and have a big bottle of shredder oil on the supply shelf). The other is to clean them very, very thoroughly then apply a dry lubricant, such as graphite or PTFE. These lubricate effectively, but because they’re a dry film or powder they won’t attract collect dust or debris.

Replace Worn Parts

3D printer parts won’t always last forever. If you need to replace parts of the printer’s frame there’s something seriously wrong, but other bits do wear out. Nozzles have a limited life, especially if you’re printing some of the more exotic filaments (anything with powdered metal in it, for example, will chew up brass nozzles pretty quickly). The silicone sock on the bottom of the hot end will eventually start to lose its flexibility, and Bowden tubes suffer steady abrasion from the filament moving through them. Eventually the worn interior will start to cause friction and can lead to feed problems. Even the POM wheels that the print head and beam move on can start to get worn.

Every month or so, give your printer an extra thorough clean and check out any parts that are vulnerable to wear. Make sure all the fans are unobstructed and working properly, too. If anything looks in less than perfect condition, replace it. Spare parts aren’t expensive, and it’s worth stockpiling an assortment of them so you can minimise down time.

Upgrade Your 3D Printer’s Firmware

Firmware is boringly invisible, but it’s also important. In fact firmware is what lets your 3D printer turn GCODE files into small plastic objects; it interprets the GCODE, converting it into a series of commands to the steppers and hot end. Depending on your printer it can also control filament break detection, auto levelling and various other features.

The firmware your printer came with works fine, but manufacturers regularly release updated versions. The latest firmware can improve performance, fix bugs or add extra menu options, so it’s always worth keeping it up to date. If your printer has a bootloader built in, upgrading firmware is simple; just format a TF card, load the new firmware onto it, stick it in the printer and switch it on. The printer will read the card, find the firmware and update itself. If your printer doesn’t have a bootloader… well, it might be time to upgrade your motherboard.

Keeping your 3D printer well maintained doesn’t take too long, and it’s well worth the time and effort. A well-maintained printer will last longer, work more reliably and produce higher-quality prints, which takes a lot of frustration out of something that already has enough to be going on with. Do you have any other printer maintenance tips? Let us know in the comments!

Leave a comment

You must be logged in to post a comment.