Food Safety For 3D Printing

I’ve mentioned before that one of the great things about a 3D printer is how it lets you print useful objects for around the house. I have quite a collection of these objects now, and I’ve talked about them in a couple of posts, but today I want to look at one particular area of the house – the kitchen.

Food Safety For 3D Printing

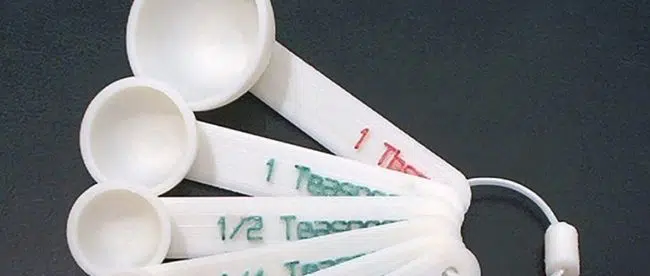

I’ve printed a few things for my kitchen, like my plate rack and spoon catcher, but so far I haven’t printed anything that’s actually going to be used for food preparation or eating. There’s a reason for that, which is that doing it safely is a lot of work. However, on my wanderings through Thingiverse I’ve come across a lot of bowls, mugs, tumblers, measuring cups and spoons. People are designing and printing things to cook and eat with – and if you want to do that, you need to do it safely.

Does this look like a good idea? If you print it in ABS it’s going to leak, badly.

Heat-Resistant Printing

There are two factors you need to take into account if you want to 3D print food-safe objects. The first one is heat. Lots of things in the kitchen get hot, and some of them can get a lot hotter than the hot end of your 3D printer. Let’s be realistic: With a hobbyist printer you’re not going to be knocking out a new spatula to flip your fried eggs with, or anything that needs to survive in the oven. If your printer can melt a material, so can your oven.

Once you start moving down the temperature scale a little, though, options begin to open up. You couldn’t print a mug from PLA, because your tea is hot enough to push it well past its glass transition temperature – the point where it starts to lose rigidity – of about 65°C. On the other hand there are filaments that can be printed into objects capable of surviving boiling water; PLA just isn’t one of them. And, surprisingly, that ultra-tough nylon that needs a 260° nozzle temperature isn’t one of them either. That stuff is hard to melt, but it turns out it’s pretty easy to make it go floppy and spill hot tea over the rim of your collapsing mug. Its glass transition temperature is just 47°C.

ABS, on the other hand, is pretty heat-resistant. It has a glass transition temperature of 105°C, which is above the boiling point of water. It’s not much above the boiling point of water, so personally I’d be reluctant to make a teapot out of it, but if you really wanted to 3D print a set of novelty soup bowls ABS is temperature-resistant enough to do the job. Polycarbonate, with a glass transition point of around 150°C, is even better.

What you really want, though is polypropylene. This is expensive, at around £50 for 500g, and it’s also horrible stuff to print with. It needs a 230-260°C nozzle temperature and 100°C on the bed, and even then it’s very prone to warping. It also likes to come unstuck from the bed unless it’s firmly glued down. However, its glass transition temperature is only a few degrees below its melting point, so polypropylene prints will stay rigid much longer than anything else. Polypropylene is also microwave- and dishwasher-safe.

Keeping 3D Prints hygienic

Unfortunately, preventing your 3D printed kitchen stuff from melting isn’t the only issue. You also need to make sure it can be kept hygienic. There’s a very good reason all the important stuff in your kitchen has smooth, impermeable surfaces; that’s so it can be kept clean. Metal, ceramics, glass and moulded plastics can all be wiped with a soapy cloth and any traces of food on the surface will be completely removed. With 3D printed plastic that isn’t always the case. Just look at the top layer on one of your recent prints. Be honest: Are you going to get all the ketchup off that in a hurry?

Good luck getting flour out of that surface texture.

As well as the characteristic texture found on horizontal surfaces, 3D printed objects also tend to have a lot of tiny surface voids that might even be too small to see, but are large enough to hold traces of food and act as a breeding ground for bacteria. If you’re going to let food contact those surfaces you need to get them as smooth as possible, and that probably means some post-processing. With ABS, for example, you can put it in a sealed box for a few hours along with (but not touching) a rag soaked in acetone. This “vapour wash” will smooth out the print, leaving a glossy and impermeable surface. You can also seal surfaces with a food-safe epoxy or polyurethane paint.

There’s another option. Horrible as it is to print with, if you get polypropylene right it can apparently produce very smooth surfaces. It also has very good adhesion between layers, which both reduces voids and keeps things waterproof.

So Is It Worth Trying?

Most of us buy a lot of stuff for our kitchens, and quite often we have the feeling that we could design them to suit our needs just a little bit better than they actually do. A 3D printer lets you do that – if you can do it safely. Obviously with some things it really doesn’t matter. If you just want a fancy bowl to keep fruit in, PLA will do fine. For that special gravy boat, however, you’ll want something smoother and more temperature resistant. Hopefully I can pick up some polypropylene filament in the near future and give it a try, because I think it’s probably the best option.

Leave a comment

You must be logged in to post a comment.