Graphene and 3D printing

EXCITING DEVELOPMENT IN THE 3D PRINTING WORLD

We’ve looked at quite a few different print materials here – various plastics, metals and even food – but one of the most exciting developments in 3D printing could be the ability to print graphene. This is a new material, one which was first made in 2004. Scientists had been sure in could exist before that but they hadn’t managed to actually create any, but already it’s been successfully printed.

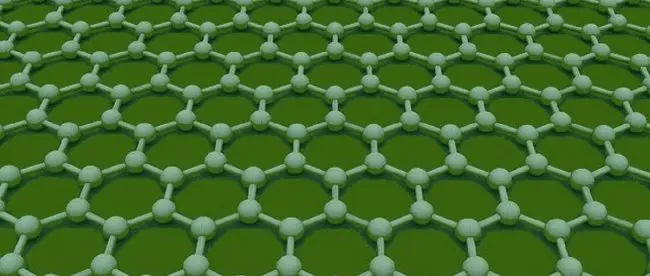

Graphene is a very interesting material. It’s a form of carbon, closely related to graphite. Most of us are most familiar with graphite in pencils but it has several other uses too. One of these is for lubrication, because its atoms are arranged in flat layers that are weakly bonded together. If the bonds break the layers can slide smoothly over each other, making it ideal as a dry lubricant. Graphite powder is popular in environments where oil or grease would attract sand. Graphene mimics one of the layers in graphite; it’s a flat crystal that’s only one atom thick. Under an electron microscope it looks like a tiny honeycomb, made up of six-sided cells.

It sounds flimsy, but graphene is actually amazingly strong. In fact it’s about a hundred times tougher than steel, if you could make a sheet of steel that thin (which you can’t). It’s also nearly transparent and conducts both heat and electricity extremely well. The problem is it’s hard to work with – normal manufacturing methods don’t work well on something that’s only one atom thick.

You can see right away that graphene could be extremely well suited to 3D printing. It’s not easy to print really strong objects without using metal, and that needs some quite expensive equipment. Easily printable graphene could change that. The big question is, how easy is it to print graphene?

Well, it certainly isn’t as easy as just loading a spool of PLA and getting started. In fact you can make a plastic filament that’s loaded with graphene, and use that in a standard printer, but some chemistry is involved. The idea is to print the object then dissolve away the plastic to leave a structure, but graphene strongly repels water; it can’t be used with any water-based print material. The solution is to use graphene oxide, which isn’t so allergic to water, then use heat treatment after printing to convert it back.

A printable form of graphene has enormous potential. As well as making very strong printed objects it’s also very useful for creating flexible circuits – its conductivity makes graphene very popular for electronics and batteries. The fact it’s in a form that can be used in a mid-range standard printer is also significant. Right now the graphene filaments are experimental but once the technology is perfected it could be available to almost anyone, turning an exotic material into one that’s available for use in everyday objects.

We probably won’t be seeing printable graphene on Amazon for a few years yet, but it is being worked on and there’s too much potential in the idea for it to be dropped. The ability to use it could be a big boost for 3D printing, but at the same time the ability to be printed would be an even bigger boost for graphene. These technologies seem to be made for each other.

Leave a comment

You must be logged in to post a comment.