Graphene-loaded filaments are in the works

EXCITING NEW POTENTIAL FOR GRAPHENE AND 3D PRINTING

New technologies are always exciting, but what’s even more exciting is when two or more of them work together to boost each other’s potential. 3D printing is a great example of that; it combined two technologies – computer assisted design, and extrusion – to create a great new way to make things. Now another innovation is being combined to 3D printing, and it looks like it could open up all sorts of possibilities. That innovation is a remarkable – and in many ways slightly weird – substance called graphene.

So what’s graphene?

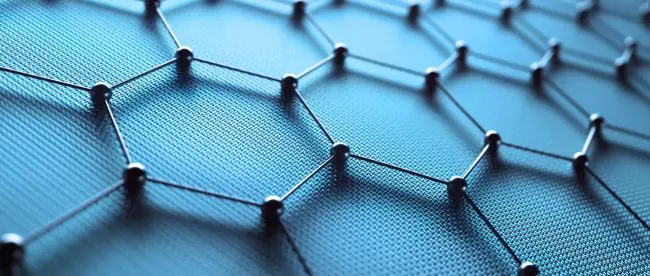

Graphene is a form of carbon. There are several of these, called allotropes, and the difference between them is how the atoms are arranged. For example diamond is carbon atoms in a crystalline matrix. Fullerenes or “buckyballs” are tiny spheres of atoms, and carbon nanotubes are hollow tubes. Interestingly, fullerenes and nanotubes both have walls one layer of atoms thick.

Basically, graphene is a flat version of a fullerene or nanotube. It’s a flat sheet of carbon, one atom thick, and each atom is linked to three others with strong double bonds to form a series of hexagons. A piece of graphene is a single molecule with no real limit on its size, and it has amazing properties.

A sheet of graphene is a hundred times as strong as a sheet of steel the same thickness, but far lighter. It conducts heat very effectively, and conducts electricity better than copper – the material of choice for electrical cables. It’s also nearly transparent.

Now two companies – filament maker Terrafilum and graphene manufacturer XG Sciences – are collaborating to produce a range of graphene-reinforced printer filaments. The idea of adding other materials to a plastic filament isn’t new – there are already filaments that contain wood, stone and even metal – but a graphene-impregnated one has some unique properties.

And what’s it good for?

Graphene is expensive, so it’s not something you’d want to use for simple projects, but for high performance applications it’s ideal. Structural parts can be made lighter and stiffer, a serious advantage for aircraft parts. There’s also a general strength advantage. One weakness of fused deposition manufacture is that projects are relatively weak in the Z axis – each layer is never perfectly fused to the one below it, so if too much stress is placed on the object the layers can shear apart. Adding graphene creates a much stronger bond between the layers, reducing or eliminating this weakness.

If you want to print anything that’s going to contain electrical components, graphene’s conductivity has a lot of properties. With a multi-extruder printer that can switch between filament types during a job, you can integrate conductive “wiring” into printed parts. Because graphene also conducts heat very well it’s good for mechanical components, too – heat gets dissipated quickly, instead of building up and creating potential failures. It’s even self-lubricating.It could be a while before graphene-enhanced filaments are widely available, but the research is happening now. The cost of manufacturing graphene means it’s probably never going to be our go-to material for everyday projects, but where you need its unique properties it’s going to make a lot of things possible. This is exciting news and we ‘ll be keeping an eye on it to see where it goes.

Leave a comment

You must be logged in to post a comment.