Recycled 3D printing materials

TURNING RUBBISH INTO A RESOURCE

3D printers are a massive leap ahead in rapid prototyping as well as a huge asset for all sorts of hobbies. In fact they have so many uses it’s hard to even think of them all – the versatility of a device that can create such a wide range of objects is immense. One lesser known fact about them, however, is that they can recycle 3D printing materials, which is good for the environment.

Most of the popular home 3D printers use plastic filament as a raw material. That’s now easy to find in craft shops and even on Amazon, in an amazing range of colours and varieties. The price is falling too, making running costs a lot more affordable than they were just a couple of years ago. However there are ways to cut them even further, and the most spectacular is by recycling plastic into new, printable filament.

You’ve probably felt frustrated already at throwing out failed projects or supports that have done their job. The bits you’re binning aren’t any use, but it’s material after all and you paid for it. So how about reprocessing them so they can be fed back into the printer for your next project? That’s now possible, because filament is something you can make at home.

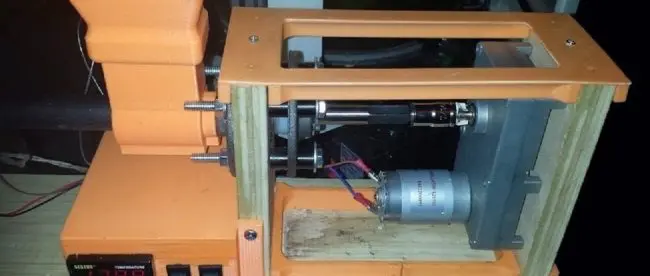

The gadgets that do this are called recyclebots, and there are plenty of them available. Like 3D printers themselves recyclebots can be bought ready to go, or built from an open source plan. They’re not complicated devices; they just take shredded or pelletized plastic, melt it in a heating chamber then extrude it through a nozzle of the correct diameter. It cools, solidifies and you have your new filament, ready to be spooled and used.

If you want to recycle 3D printing materials you’ll need a plastic shredder too. Many recyclebot designs include these; they’ll grind lumps of plastic into small strips or pellets that can be loaded into the recyclebot’s hopper. Once there a screw feeder carries them through the heating chamber – this is usually heated by simply wrapping it in resistance wire – and finally forces it through the nozzle. If you run out of things to recycle you can also buy plastic pellets in bulk bags; this usually works out a lot cheaper than buying ready-made filament.

There are some more ambitious options too. A lot of packaging and consumer items are made from printable plastics, and these can be recycled into filament too. Many bottles are made from PET; it can be shredded, melted and extruded, then used for printing. Even many plastic bags can be reprocessed into raw material for your printer.

Recycled plastic can be an incredibly cheap resource, but it does have downsides. It doesn’t offer the choice of colours you’ll get if you buy filament (or pellets), and you need to be careful not to mix different types of plastic. However for making test prints, or just experimenting with your printer’s capabilities, it’s great. If you’re planning on using your 3D printer a lot a recyclebot might be the perfect addition to your setup if you want to recycle 3D printing materials.

Leave a comment

You must be logged in to post a comment.