Review – PrimaSelect Metal Filament

A few months ago I reviewed a wood-effect 3D printing filament that contained real wood, or at least bamboo. It was an interesting material to work with, and if you get the design right it lets you print objects that are fairly convincingly wooden. Ever since then I’ve been wondering if the same applies to metal-enhanced filaments, and this week I decided to find out.

PrimaSelect Metal Filament

A few days ago the postman brought me a spool of PrimaSelect metal filament. This is technically a PLA filament, but in fact it’s 80% powdered metal by weight. It comes in three varieties – brass, copper and bronze – and we decided to test a 750g roll of bronze.

This certainly isn’t the cheapest filament we’ve tested. It cost £43 for the spool, and when it arrived I was startled by how little there was. It didn’t look like a full spool at all. The mystery was soon solved, though. Filament is sold by weight, and this stuff is heavy. PrimaSelect say it’s three or four times as heavy as standard PLA and I’m definitely not going to argue.

Does It Work?

As well as being heavy, this filament is also very brittle. It needs careful handling, otherwise you’re going to have a lot of frustrating breaks. The first time I tried to feed it through the extruder I ended up having to fish a couple of inches out of the works and start again. The second attempt was more successful, though, so I told the Ender 3 to run off another of the skulls I did a while ago when I tried out luminous filament. And, about 10% of the way through the job, the filament snapped off a few inches above the extruder.

At 3D Printing UK we don’t admit defeat easily, so I cleared the remnants out of the extruder again, threaded the end back in and tried again. And, this time, it printed out successfully!

Does It Look Like Metal?

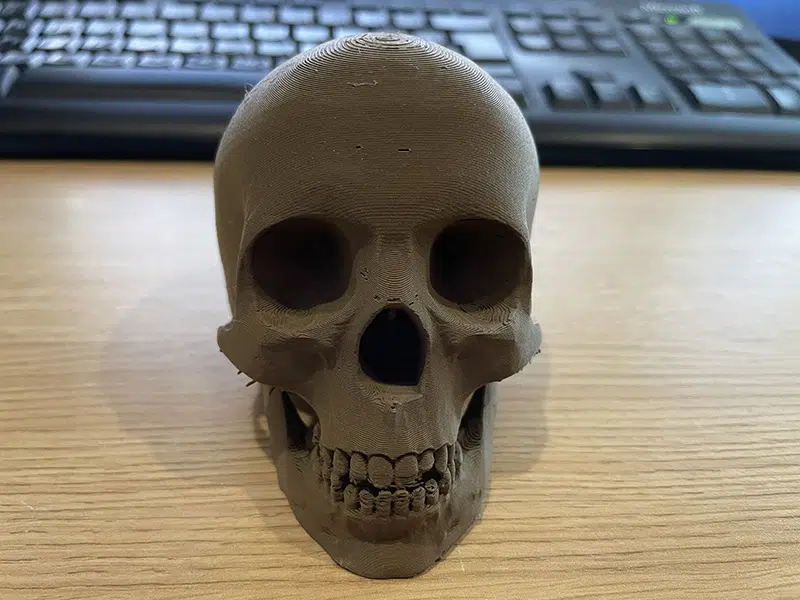

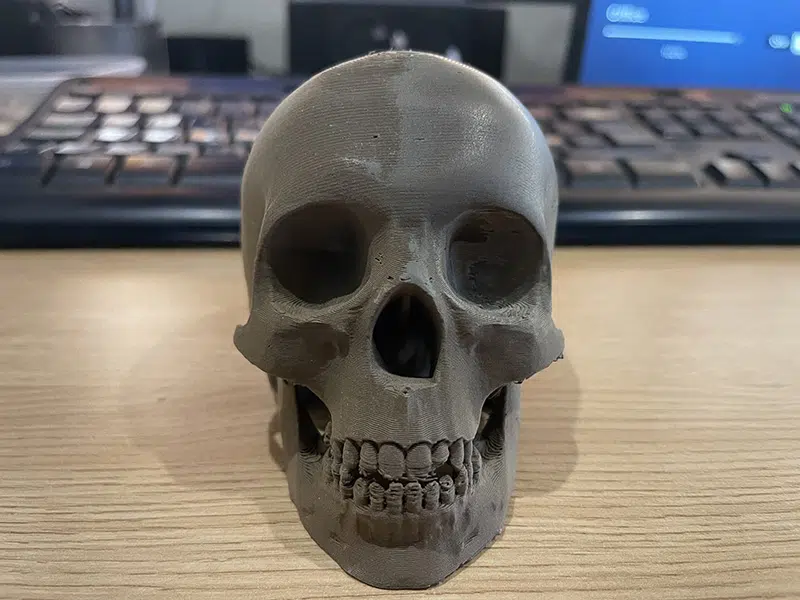

After nine hours I had a skull that looked like it was made of… clay. Yes, really. Clay. I wasn’t actually surprised at this though, because I’d already read the manufacturer’s post-processing instructions and that’s what they said it would look like. They also suggested polishing it in a rotary tumbler. I don’t have one of those, so instead I followed their second suggestion, which was to sand it with fine sandpaper. They did suggest 600-grit paper and the finest I had was 240-grit, but I gave it a shot anyway. It actually worked pretty well; PLA isn’t usually too happy about being sandpapered, but this seemed to hold up very well – and, after a little bit of work, it developed a nice smooth finish. At first it looked pretty plasticky, but after I did some more work with a duster and some Brasso it developed an unmistakable metallic gleam.

Another thing I noticed is that while the skull mostly feels like plastic there are definite hints of metal in there. It has a cold feel to it, and it’s far weightier than you’d expect a 3D-printed object that size to be. Despite the brittleness of the filament the final object feels strong and reassuringly solid.

The Verdict

The skull I printed doesn’t look like it was cast from bronze, but I wasn’t using the recommended fine sandpaper to finish it with – and, even so, it still has a definite metallic look when the light catches it. I’ve now ordered a pack of that, and I’ll add some updated photos to a future post. I’m hoping that the finer grit will sand away the outer layer of plastic without also digging out the particles of metal, leaving a more obviously metallic surface behind. I’ll do my best to get a sample of the copper filament too, but for now I’m going to give PrimaSelect’s metal filament a thumbs up.

Leave a comment

You must be logged in to post a comment.