Review – SRY-Holster Polycarbonate Filament

This week we thought we’d continue our exploration of some of the weird and wonderful 3D printer filaments on the market. Last week we looked at some very interesting bronze filament, which has a lot of potential for making decorative objects that look like they’re made from real metal. Today it’s time for something completely different – a material that should be perfect for making very strong parts. Polycarbonate filament.

PC – What Is It And Can We Print It?

Polycarbonates are actually a class of materials, not just one. A polycarbonate is a plastic that has a carbonate group – a sort of molecule with carbon in it – in its chemical structure. For various chemical reasons carbon atoms form very strong bonds, and that makes polycarbonates very strong materials. They’re used in a wide range of products that need to be light and strong – aircraft parts, for example. You’ll find them in electric insulators and many electronic components. Transparent polycarbonates are used to make bottles, DVDs, safety glasses and car headlight lenses. They’re amazingly useful substances, and they can even be 3D printed.

Having said that, 3D printing with polycarbonate is certainly possible – but, on a home printer at least, it isn’t famously easy. In fact I’ve read a lot of horror stories about trying to print the stuff. It won’t stick to the bed even if you smear it with cyanoacrylate. It needs very high hot end and bed temperatures. And even if you do get it to print, the layers will immediately separate. Everything I’d heard was telling me that this stuff is completely hellish to print with. So we decided to get some and find out.

What Did We Get?

What we ended up buying was 1.75mm black polycarbonate filament from SRY-Holster. This stuff isn’t cheap; we ordered 100g of it and it still cost £22.51. This is definitely a filament you’d keep in reserve for when it’s really needed. It is also available in 500g and 1kg batches, and the price per 100g falls rapidly as the size goes up.

I have to say I wasn’t impressed at the packaging. The filament turned up in a loose coil, wrapped in bubble wrap – no spool, and no vacuum seal. For a material that sucks up moisture as greedily as polycarbonate that just isn’t good enough. Honestly, when you’re paying over £22 for 100g of filament – at a significant markup over buying a larger quantity – the least they could do is wind it onto a small spool and vacuum seal the stuff. A big thumbs down for the packaging, then.

On the other hand the filament itself feels good quality. It’s completely different to the bronze filament, which was extremely brittle; it genuinely did break more easily than uncooked spaghetti. The polycarbonate was a different story. It’s quite supple and very springy. If PLA filament kinks I usually find that any attempt to straighten the kink ends up with it breaking, but the PC is a lot more resilient.

Printing With Polycarbonate

Anyway, now that I had the filament I decided to test it in the traditional way, by printing a Benchy. Everyone agrees that when printing with PC the first layer is even more vital than usual, so I ran the 3D printer through its self-levelling routine. Then I gave the print bed a generous wipe with cyanoacrylate and set the temperatures. Most sources I found suggested setting the nozzle temperature to 290°C and the bed to 135°C. Unfortunately these temperatures are out of reach of the Ender 3, so I had to settle for 260°C and 110°C. Then I loaded the Benchy file and set it running.

A few minutes later I stopped it again, because the polycarbonate filament wasn’t sticking to the bed. I did some more research and dropped the print speed to 20mm per second, then tried again. It still didn’t stick. I gave the bed a good clean then realised I was low on cyanoacrylate, so for lack of anything better I sprayed it with my trusty can of 3DLac – and it worked!

Well, it sort of worked. Remember I mentioned that the filament is pretty springy? About half way through the (very long) job the coil sprang right off the filament holder and turned itself into the sort of horrible bird’s nest tangle that sea fishermen know so well. I frantically pawed at the mess and managed to free up enough filament to finish the job, but at some point I have to untangle the rest of it. Anyway the Benchy came out looking reasonably good, allowing for the fact I’d forgotten to turn supports off. There were a couple of pimples on the hull, but apart from that surfaces were smooth, with little in the way of visible layer lines, and details were quite good – not the crispest I’ve seen, but definitely acceptable. The problem came when I tried to pry the Benchy off the build plate. Despite everything I’d heard (and experienced) about adhesion problems, it was stuck fast – and when it finally did pop off it left a good chunk of the bottom layer behind. This wasn’t strictly speaking a layer adhesion problem either, because only parts of the layer stayed on the bed.

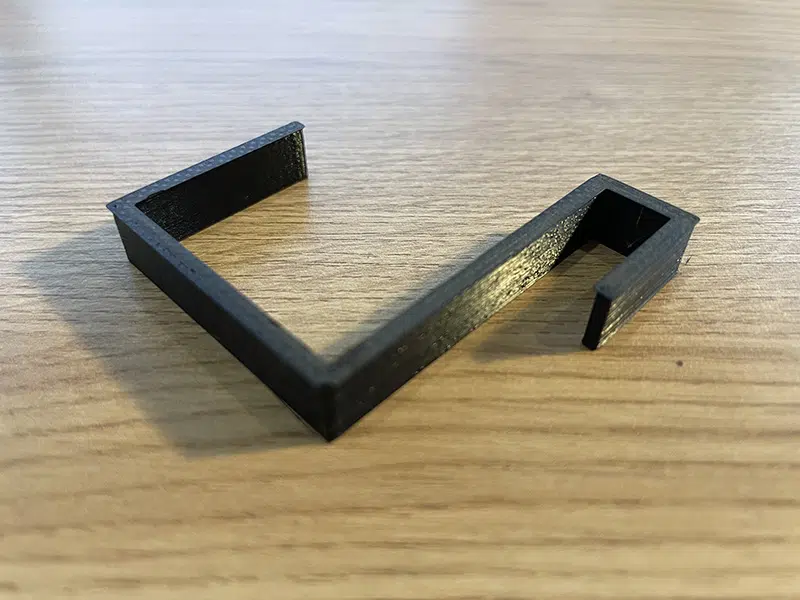

I felt quite optimistic, though. Now that I’d established that the stuff actually would print, I decided to try one of my strength test hooks. These don’t have a lot of area in contact with the bed, and everything I’d read said I’d need a raft to have any chance at all of getting a successful print. I decided to try it without one, though, and somewhat to my surprise this print worked, too – perfectly, as far as I can tell. The hook didn’t show any sign of layer adhesion problems, so I hooked it over my office door and started loading it with books. It held up amazingly well, until the 33rd book. At that point there was a snapping sound, the bag of books crashed to the floor and the hook disappeared. Seriously, I have no idea where it went. If I find it somewhere in the tangle of cables under my desk I’ll report back on its condition, but for now the main thing is that, in an identical test, it held one more book than the nylon hook I tested last year. This is strong stuff.

The Verdict

Did I mention that I hated how the polycarbonate filament was packaged? For the price I was seriously unimpressed with the lack of attention paid to packaging, but I’m assuming that if we’d ordered a larger quantity it would have come on a spool and properly packaged. If not, well, that’s a second thumb down.

As far as printing the stuff goes, though, it’s actually much easier than I’d feared. Yes, it’s difficult to print. This is not PLA. With some tuning and experimentation, though, there’s no reason why you can’t get good quality – and very strong – polycarbonate objects out of a hobbyist 3D printer in the Ender 3 class. If you’re willing to pay the steep price, and spend some time getting your printer dialled in just right, SRY-Holster’s polycarbonate filament is a very promising material.

Leave a comment

You must be logged in to post a comment.