What Filament – PLA Or ABS?

One of the great things about 3D printers is the variety of materials you can print with; even an entry-level machine should be able to print with at least a couple of different types of filament. Then we make it all irrelevant by using PLA 95% of the time.

There’s nothing wrong with PLA, of course. It’s an economical material that gives decent results, and for beginners it’s hard to beat. It’s not the only option for everyday print jobs, though. Without getting into the more specialised types of filament, there’s another material that can be a great option for routine projects, and that’s ABS.

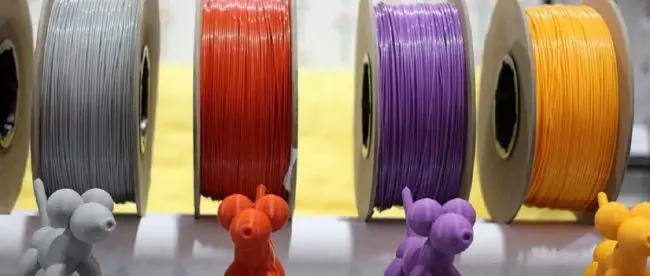

Like PLA, ABS is a thermoplastic material – it softens when you heat it, then hardens again as it cools. They both cost about the same, with a 1kg spool starting at around £20 if you shop around. Apart from these basic similarities, though, they’re very different materials. Let’s compare them from the 3D printing point of view.

Keeping It Simple?

There’s no doubt that PLA is easier to work with. It melts at a lower temperature, with anything from 190°C to 220°C, while 220°C is the lower end of what works for ABS. The higher temperatures involved make ABS a lot more prone to warping if you’re not careful; it’s notorious for the first layer coming unstuck at the corners and curling up. If you want good results a heated bed is pretty much essential, and an enclosed print chamber will be a big help, too. A lot of printers, especially entry level ones, will struggle with ABS.

If your printer can handle the temperature, though, ABS does have some advantages. PLA filament can absorb moisture from the air, and when it’s heated that leads to bubbles and broken filament. It’s also prone to stringing. ABS is much less vulnerable to these issues.

If you want to make parts that actually need to withstand temperature, ABS’s higher melting point becomes an advantage. PLA starts to lose strength at temperatures as low as 60°C, but ABS is a lot more heat-resistant. It’s also just generally much stronger. PLA is a very brittle material and gets more so with age; ABS is a lot tougher. It’s also longer lasting. PLA is a biodegradable plastic

Finishing Touches

Straight out of the printer, both materials look pretty much the same. With a little work, though, some dramatic differences appear. For example, you can polish ABS by simply rubbing it with a cloth dipped in acetone. That helps to hide the layers, and you can achieve a high-gloss finish quite easily. That makes ABS a better choice for ornaments. It’s also much easier to sand – PLA can react badly to sanding – and a far better choice if you want to do any drilling or machining.

We think PLA and ABS both have their place, but if you have a heated bed ABS is probably a superior material for most jobs. It’s a little trickier to get things to come out right, but when they do you’ll have prints that last longer, are more practical as working components and can be finished to look a lot better. Best of all, it costs about the same as PLA. If you haven’t tried ABS yet, give it a go and see how you and your printer get on with it.

Leave a comment

You must be logged in to post a comment.