What Have I Been Up To In The Last Week?

Today I was planning to tell you how our 3D scanner project was working out, but… no, actually I am going to tell you that, but it won’t take long. So I’m going to ramble about a couple of other things as well.

What’s Up With The Scanner?

Over the last week I’ve been printing the bits for a hand-operated 3D scanner for our 3D scanner project that uses photogrammetry to turn a series of pics from a phone camera into a 3D model. Yesterday the last component came off the Ender 3, so I cut away the supports, cleaned up all the bits and started assembling them.

I’d been a bit worried about how the four large sections of the base would go together, but that actually worked out pretty well. I gave all the edges a scrape with a craft knife, lined them up and tapped the sections into place with a small hammer.

The innards of the scanner all go together neatly, and there are holes to thread the headphones through. All you have to do is get the volume control into the cutout, with one of the buttons in the center, then wedge it in place with the curved stopper. After that you can assemble the crank handle and cog wheel on top of it, finishing off by dropping the turntable into place.

The only problem is that it doesn’t work.

No matter how I fiddled with the volume control, it’s just slightly too low for the wheel to press the button. I designed and printed a modified stopper, with a small wedge to raise the control slightly, but that didn’t work either. If the control is high enough for the wheel to press one button, it’s high enough that the other button is being pushed against the base; it seems they cancel each other out. I’m now looking at designing a separate holder that will slot into the base and avoid this problem.

I’m also collecting the bits to build a different, more advanced scanner. This one also uses a mobile phone as the camera, but it’s controlled by an Arduino board.

ABS Filament

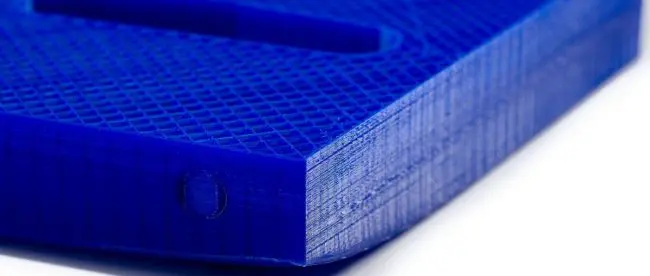

I’ve been experimenting with a spool of ABS filament over the last couple of weeks. It’s been frustrating at times. The Ender 3 should be capable of printing quite easily with ABS, and indeed I managed to produce a quite good 3D Benchy (without supports, too). However, when I tried to print a holder for my USB sticks and TF cards it warped like a banana, and despite trying seven or eight times I was completely unable to print one of my test hooks to see how strong it is. Every single time, the layers came unstuck halfway through the job.

ABS has a reputation for warping, and even with a heated bed and enclosure this is a real problem. Playing with speed and temperature settings seems to have limited effect. So far the best solution seems to be using a wide brim and hoping that sticks it down firmly enough. A squirt of 3DLAC spray helps a little, too.

On the other hand, I decided to print one of the parts for the more advanced scanner I was talking about as part of our 3D scanner project, and forgot to change the spool from ABS to PLA. The part in question is a 6” planetary gear inside a print-in-place bearing ring. It came out perfectly.

Filament In General

The first major issue I had with the Ender 3 turned out to be caused by damp filament. The PLA had picked up enough water that, as it approached the hot end, it was swelling and jamming. I fixed that by leaving the spool in my dehydrator overnight, which was effective, but I haven’t had to do it since. Why not? Well, I picked up a pack of vacuum bags. These will hold three 1kg filament spools or six 250g ones, and the pump can create a vacuum strong enough to actually bend the spools (don’t do this). I throw a handful of silica gel sachets into each bag to absorb any moisture that does make its way inside. As long as I keep the zip seals clean these bags hold their vacuum for weeks, and seem to do a great job of keeping my filament dry. They come in larger sizes, too, but the medium ones I got are probably ideal for filament.

Leave a comment

You must be logged in to post a comment.