UV Printers – What Are They?

Recently a couple of people have asked me about UV printers, so I thought I’d talk about them a little. They’re not 3D printers, but they do have a few things in common with them and they certainly aren’t normal printers, either.

How Do Printers Work?

There are two main technologies used in conventional printers. Inkjets are the simplest. They spray tiny droplets of ink onto a surface to build up a picture, line by line. This is a cheap and simple way to do it, but it’s also slow. Laser printers are a lot more complicated, but faster and give better results. They use a laser to “draw” an electrically charged image on a drum. The charged areas then pick up toner and transfer it to a sheet of paper; finally, heated rollers fuse the toner onto the paper.

The problem with both these methods is that they can only print on paper and some similar materials. An inkjet’s ink needs to soak into the print material; a laser needs to roll the print material round the drum then feed it between the rollers. That’s easy with paper or a sheet of labels, but it won’t work with a T-shirt, metal sign or slab of granite.

So What’s New?

UV printers overcome a lot of these drawbacks. Normal printer ink is solvent-based; it stays liquid until the solvent evaporates, and if it hasn’t soaked into the surface by then it will quickly smear or rub off. UV ink isn’t solvent-based; it hardens as soon as you shine a UV light on it, and bonds firmly to whatever surface it’s on without having to soak into it.

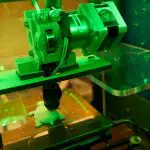

Unlike laser printers, UV printers don’t need to roll their print media round a drum. A flatbed UV printer lets you print onto rigid, and often quite thick, objects. Sheets of metal, plastic tiles, slabs of stone – they can all be loaded into the printer.

You can also use UV printers on delicate surfaces that would be damaged by heat, which isn’t possible with laser printers. The ink cures almost instantly, so only a very quick flash of UV light is needed. Conveniently, this makes the printers extremely fast. It also means there’s no risk of the ink getting smeared before it has a chance to dry.

Before UV printers were invented the normal way to print on inconvenient materials was silk screen printing. This is a cheap and effective technique, but it has serious limits. For example, you’ll never reproduce a colour photograph with silk screen. You can do that with a UV printer.

Unlike most other technologies, UV printers can also print vivid, solid white on a coloured background. They can print on textured surfaces, even completely non-porous ones. They work well on fabrics, where an inkjet would produce blurry prints and a laser wouldn’t work at all.

Can I Get One?

So far, UV printers are a commercial technology. They’re widely used for printing clothes, signs, packaging and high-quality stationery. The price is much too high for home use, with basic models still costing over £10,000, but it’ll come down. We’ve seen that happen with laser and 3D printers – I have a £90 3D printer in my office right now – and UV models could easily be the next thing to make it into our homes.

Leave a comment

You must be logged in to post a comment.