3D Scanning The Affordable Way?

A couple of weeks ago we were chatting about how 3D printing technology is getting better and cheaper all the time, and the conversation drifted onto 3D scanners. I’ve talked about these before, but up to now we hadn’t considered actually getting one. On the other hand, why not?

Well, because they can be pretty expensive is why not. There are some affordable ones on the market now, but we’ve been reading the reviews and right now we’re not convinced that, even at £80 or so, they’re great value for money. One of them specifically says “it is not suitable for scanning irregular and complex objects, only scan nearly cylindrical object”. Hmm.

However, our research did turn up one option that’s a lot cheaper than £80. In fact it’s so cheap that, if it’s capable of scanning objects at all, it pretty much has to be value for money. How does it manage that? Simple; it’s fully printable, and the only extra component it needs are a smartphone and a set of earphones with an inline volume control.

3D Scanning Techniques

There are two ways to make a 3D scan of an object. The best one is to scan the object with a laser and use the reflected energy to build up a 3D model of it. This is expensive, though; it needs a lot of processing power to achieve decent accuracy, and it isn’t the sort of device that’s going to be affordable for a while yet.

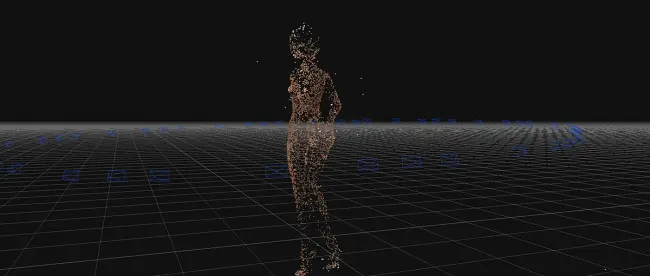

The other way is through a process called photogrammetry. This technique works by analysing a series of photos taken of an object from different angles, identifying points on the object’s surface that appear in multiple photos, and using the relation between how each photo shows the points to calculate where they sit in 3D space. These points can then be used to construct a mesh of the object, and a programme like FreeCAD can turn that mesh into an STL file that you can slice and print.

How Does This Work?

What we’ve found is a design for a photogrammetry-based scanner that uses a mobile phone as its camera. The object to be scanned is placed on a turntable, which is rotated using a small hand crank. This crank also repeatedly pushes the volume control on the phone’s earphone cable, triggering the camera. The smart thing here is that because the same crank works the turntable and the camera, they’re automatically synchronised.

Once the object has turned through a full revolution you upload the photos to your computer and drop them into a photogrammetry programme. This will analyse them and generate a 3D mesh, which can then be turned into an STL file, sliced and 3D printed.

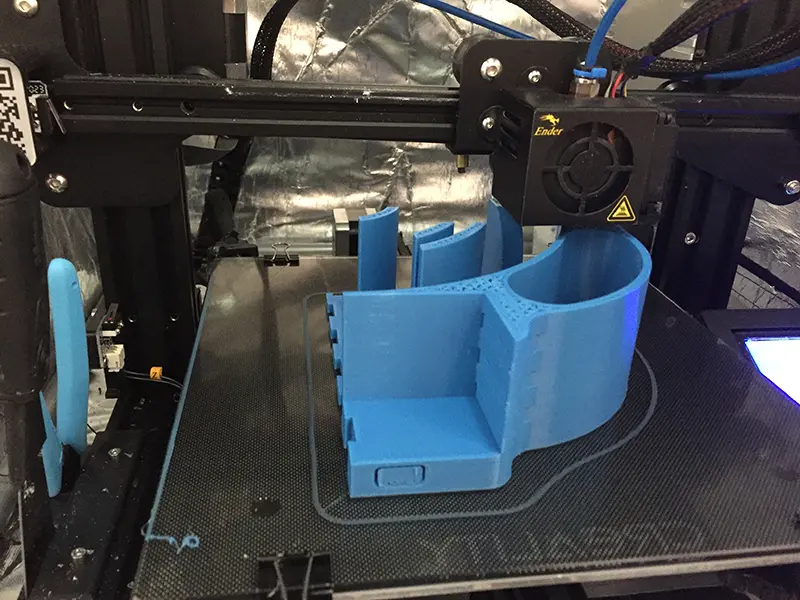

Of course, the question is how well this simple scanner can capture 3D shapes. Will it take enough images, consistently enough and from the right range of angles, to let the photogrammetry software do its stuff? I have no idea. However, I’ve downloaded the software and the first component of the scanner is printing right now. Next week I’ll be building and testing it, so come back soon to find out how it worked!

Leave a comment

You must be logged in to post a comment.