Strength Testing – Mr Universe For Filament

Over the last few weeks we’ve been experimenting with different 3D printing materials, and we’re building up a decent collection of filaments by now. Later this week we’ll be looking at some PLA options to consider if you want to print decorative stuff for around the house, but today I thought I’d answer a more practical question – what’s the strongest filament you can print with an Ender 3?

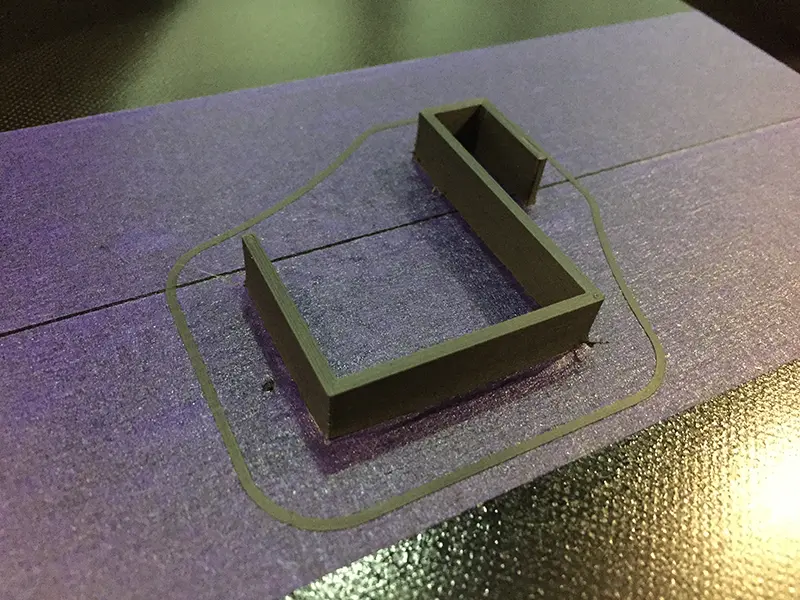

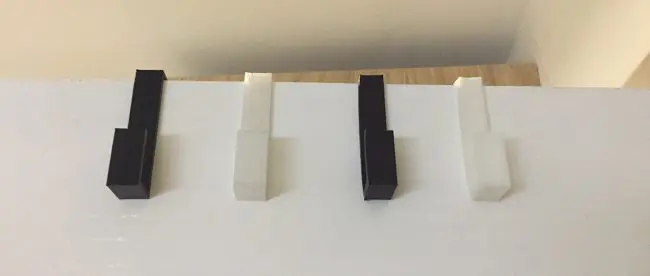

To answer this I designed a hook that would fit over the top of my office door. I deliberately kept this simple, and built in some angles to see if those would be weak spots. I sliced it to print in super quality (0.12mm layers), lying on its side for maximum strength – I wanted to test the actual material, not just see how quickly I could separate layers. Then I printed out four copies, all identical except for the filament. The materials I used were PLA, PETG, HIPS and nylon. I have TPU too, but I didn’t bother with that because it’s flexible and you’d have to be fairly special to try making a hook out of it. With the hooks printed, I fixed them along the top of my door ready to be tested.

I went for a simple design that didn’t give the material any help.

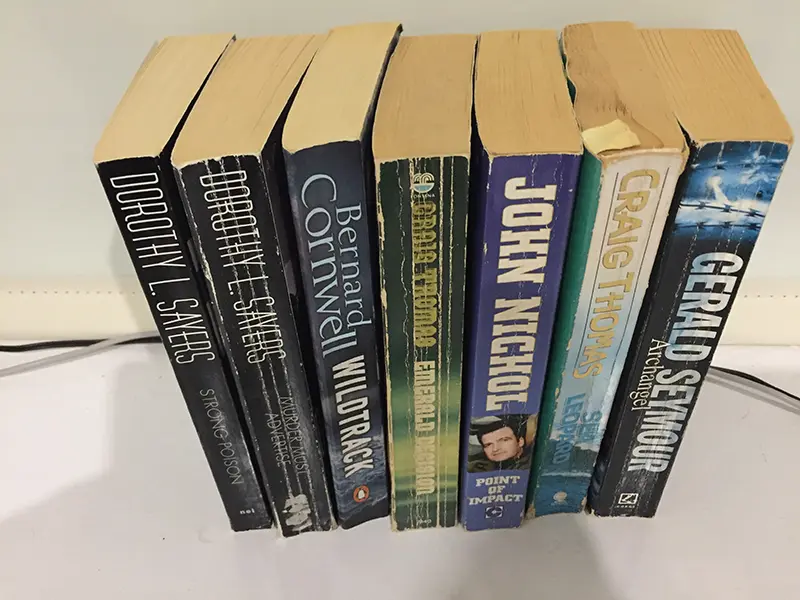

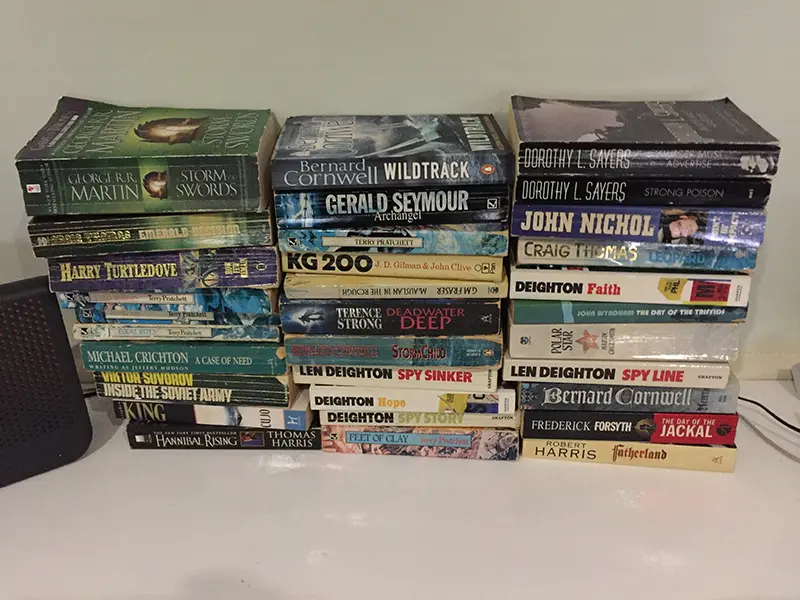

The test itself was simple: I hung a bag from each hook in turn, then added books to the bag one at a time until the hook failed. Then I picked up the books from the floor and counted them. Let’s see how they all did.

PLA

PLA is most people’s go-to filament because it’s easy to work with and the results look pretty good, but it isn’t famously strong. I didn’t have great expectations for this hook, and it turned out I was right. By the time I added the fourth book the hook was bending visibly; at book number seven there was a painful sound and the bag fell off. Interestingly, the hook snapped most of the way through at the inside angle, but one filament thickness peeled off and held the whole thing together. The layers didn’t separate at all.

This is what it took to destroy our PLA hook.

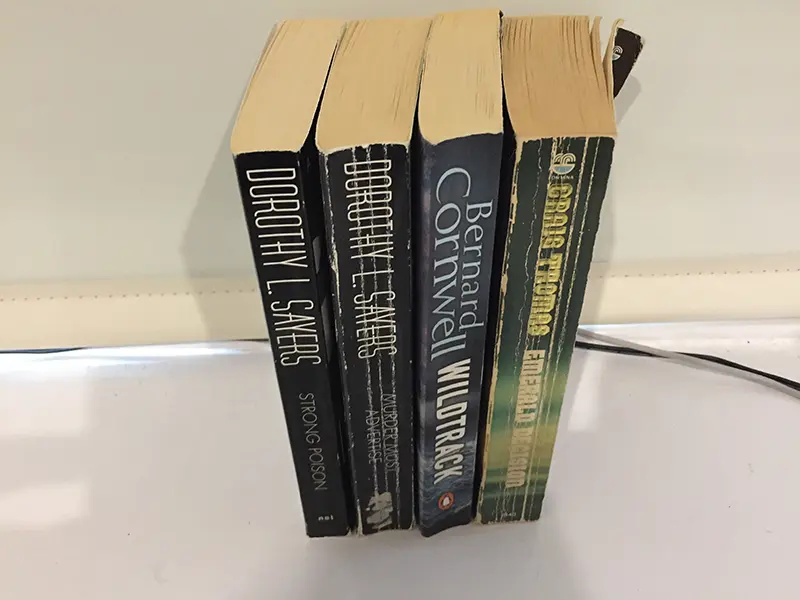

PETG

I’m quickly getting to hate printing with PETG. It’s finicky stuff, it doesn’t like the Ender’s new glass bed, and I’ve had some layer adhesion issues too. It took four attempts to get a finished hook, the same as the benchy I printed with it a few weeks ago. That hook turned out to be pretty good, though. In fact it held up perfectly until the 20th book. Again, it failed at the inside angle. This one didn’t actually snap, though; again, the layers stuck together but the plastic delaminated along the print lines within each layer.

Our PETG hook failed under this lot.

HIPS

I like HIPS because, although it prints at the top end of the Ender 3’s temperature range, objects come out looking very nice. How strong are they, though? Oh dear…

Nope nope.

Four books. Well, that’s a bit rubbish. Again, it delaminated within layers, not between them – and, like the PETG, it didn’t snap. This surprised me a little, because it feels quite brittle.

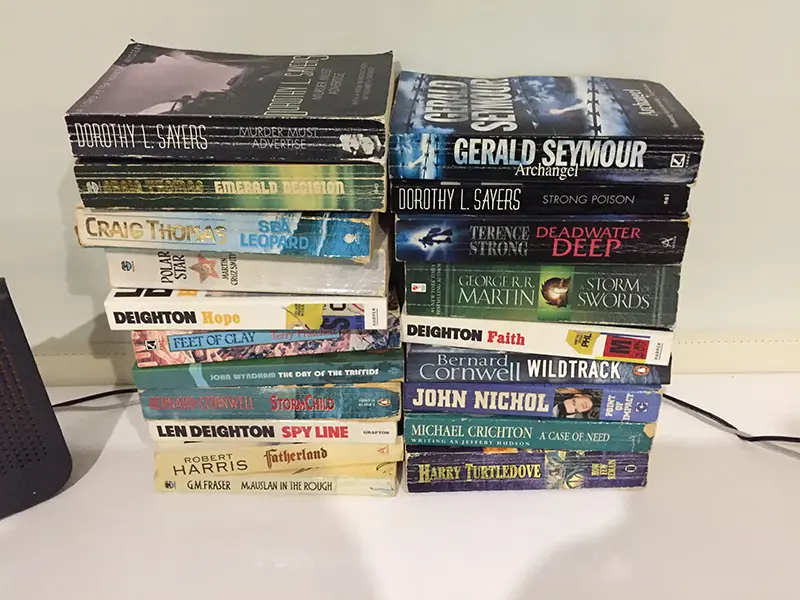

Nylon

I expected the nylon hook to be the strongest, and I was right again. Twice in one year; sometimes I amaze myself. Anyway, it wasn’t even close. It took 32 books to bring the by now rather heavy bag crashing down, and even then the hook actually seemed undamaged; it had simply flexed enough to let the bag slip off. I emptied the bag, hung it back up and redid the test. Once again it failed on the 32nd book, so I’m pretty sure it really was undamaged. Bear in mind that I didn’t even try to design a profile that would maximise its capacity; this was just a flat strip of printed nylon 10mm wide and a hair under 2mm thick. I’m honestly quite impressed at how tough it is.

This stack of books weighs just shy of 7.5kg – over 16lb. Our nylon hook bent when I added Hannibal Rising.

The Verdict

Well, this isn’t much of a surprise, is it? If you want a material that’s easy to print, stick with PLA. If you want it to look good, HIPS is worth looking into. But, if it’s strength you need, nylon reigns supreme.

Leave a comment

You must be logged in to post a comment.