Direct Sound Printing – Is This A Game Changer?

In the last couple of weeks we’ve looked at two new types of 3D printer, which both have a lot of potential. As exciting as they are, though, they both use basic technologies we’re already familiar with. Fused Granular Fabrication uses pellets or granules instead of filament, but the material still ends up being forced into a hot end and melted. Viscous Lithography Manufacturing transfers resin using a transparent film, instead of doing all the work in a tank full of the stuff, but the resin is still hardened with focused light.

Now Canadian researchers have come up with something completely different. A team at Concordia University in Montreal is working on 3D printers that use sound to create objects from liquid resin. At a very basic level it’s similar to stereolithography – you pump energy into the resin to selectively harden it – but actually it’s very different and opens up some really interesting possibilities.

How Does Direct Sound Printing Work?

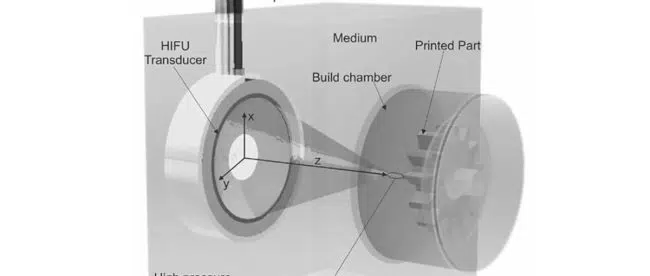

The new technology is called Direct Sound Printing, and it’s based around using a very precise ultrasound transmitter to create solid shapes inside a tank of resin. The light emitters in a SLA or VLM 3D printer can only harden the surface layer of resin, but the ultrasound emitter in a DSP printer doesn’t have this limitation. The energy it emits can be focused at a specific depth within the resin, and until it’s focused it isn’t intense enough to do much. When it is focused, though, interesting things start to happen.

When the ultrasound energy is focused, it becomes intense enough to cause cavitation – the formation of tiny bubbles – in the resin. We think of bubbles as fragile things, but in fact they can be very powerful. If you’ve watched films like The Hunt for Red October you’ll know that submariners try to avoid creating cavitation around their propellors because it’s noisy, but in reality all ships try to avoid cavitation, because thrashing a prop through the tiny but very energetic bubbles is a great way to tear up its surface and eat away its edges. Cavitation bubbles can reach very high pressures and temperatures, easily high enough to damage a metal propellor. DSP exploits that pressure and heat to cause chemical reactions in the resin.

The Concordia team say their ultrasound technology can create bubbles with an internal pressure of 1,000 bar and temperatures around 15,000 °C – that’s a thousand times the pressure of Earth’s atmosphere at sea level, and three times as hot as the surface of the Sun. Yes, I had to read those numbers a couple of times before they sank in; they’re huge numbers. The bubbles themselves are tiny, though, so if you were worried about unleashing those sorts of forces inside a printer, don’t be. The conditions inside the bubbles might be extreme, but they’re localised inside a very small area and only exist for a fraction of a second.

So What’s It Good For?

So far it’s very early days for DSP 3D printer technology, so it’s hard to predict how it will develop, but there are some huge potential advantages. Firstly, because the ultrasound can be focused at a selected depth inside the resin, objects don’t need to be created one thin layer at a time. If the emitter can be aimed and focused quickly, it could be a very fast printing method.

The possible advantages of DSP go well beyond speed, though. Because the ultrasound waves can pass through other material, unlike light, it should be possible to print inside an existing object. One potential use for that would be to repair internal damage without having to cut something open; for example engineers could repair an aircraft from outside its structure, by printing internal supports. The technology could even be used to print medical implants inside a patient. I’m not 100% sure how that would work, but my guess is it would involve injecting resin into the target area, printing the implant then removing surplus resin. That’s a little invasive, but a lot less so than surgically inserting an implant.

So far Direct Sound Printing has been tested with polymers and ceramic material. The team are also planning to try it with polymer-metal composites, and hope they’ll eventually be able to print with pure metal. If that works, this technology could revolutionise a lot of industries. Its ability to print inside other objects makes it unique; no other 3D printing technology can do this right now. Will it ever be affordable enough to show up in a home printer? I don’t know – but I hope so!

Leave a comment

You must be logged in to post a comment.