Beyond PLA – Alternative 3D Printer Filaments

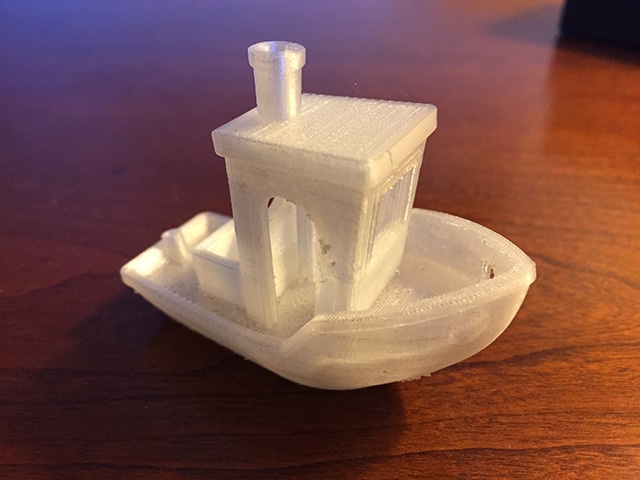

Up to now everything we’ve done with our Ender 3 has used PLA, but there are plenty of alternative 3D printer filaments on the market and we thought it was time we gave some of them a try. Last week we ordered a pack of four different materials – PETG, HIPS, nylon and flexible TPU – and to compare them with PLA we printed off a small fleet of 3D Benchy tugboats. Over the next couple of weeks we’ll cover each of these materials in more detail, but for now here’s a comparison of what they’re like to print with.

HIPS

High Impact PolyStyrene is a blend of polystyrene and synthetic rubber that’s less brittle than pure polystyrene. It’s often used as a soluble support for ABS prints – it dissolves in limonene – but it’s a good print material in its own right.

HIPS prints at quite high temperatures, comparable to nylon, so I was unsure how well it would work on the Ender 3, but once I was done wrestling with it (the filament is very stiff and springy, and the whole spool tried to unwind itself as I loaded it) it actually printed easily with the hot end at 250°C and the bed at 75°C. The finished print was very crisp and detailed, with layer lines almost invisible. It’s still quite brittle and my first attempt broke while I was removing the supports from inside the wheelhouse, but I was very impressed with the print quality and ease of printing.

Nylon

I was really worried about printing this on the Ender, because nylon needs high temperatures and is notorious for poor adhesion if it cools too quickly. After loading it I cranked both temperatures up as high as I could – 260°C for the hot end and 110°C for the bed – and kept the enclosure zipped up for the whole job. The print came out looking truly awful – a mass of stringing and mysterious blobs that weren’t in the 3D model – but once I’d cut away the mess it was actually pretty good. It’s also very strong, and despite visible layers there don’t seem to be any adhesion problems at all. A definite, and surprising, thumbs-up for nylon.

PETG

Out of all the alternative 3D printer filaments tested I didn’t anticipate any issues with PETG; it prints at around the same temperatures as ABS, so at 220°C on the hot end and 50°C for the bed it should have worked fine in the Ender 3. Well, it didn’t. My first four attempts at turning out a PETG Benchy failed. It seemed to run fine for the bottom half of the hull, then the nozzle would block. Once, just for variety, nothing stuck to the bed and I printed out a bird’s nest of stringy plastic. On the fifth attempt, however, I pushed the bed temperature up to 75 °C and things went much more smoothly. The finished Benchy has one blemish on the hull where a support seems to have stuck too firmly, but overall print quality is quite good and the print seems strong, with good layer adhesion.

Flexible TPU

Flexible filament doesn’t have a good reputation for 3D printers that feed the extruder through a Bowden tube, so I left this one for last in case it gummed up the works. As soon as I unwound the filament from the spool I could sense it was going to be trouble. It felt like a warm liquorice bootlace; soft, extremely floppy and very much not the sort of thing that’s going to work well in a Bowden tube. Even trying to feed it through the extruder was a nightmare.

And then it printed just fine.

With the hot end at 220°C, the bed at 70°C and speed set to 75%, the bendy Benchy printed slowly but almost without a hitch. Some of the supports collapsed but that didn’t seem to affect the hull at all. The final print was a bit rough in places, but layer adhesion was good and it was actually the easiest to remove the supports inside the wheelhouse from. The Benchy is a tough test for any filament, but the Ender 3 managed to print a decent flexible one; that’s quite impressive.

The Verdict

I was a little surprised at some of the results I got here. Everything I’ve read about the Ender 3 suggests it’s best with filaments that print at relatively low temperatures – PLA, PETG and, if you have an enclosure, ABS. In fact PETG was a horrible failure, while the high-temperature ones performed pretty well – the HIPS print was very nice, and while the nylon benchy looks a bit rough it cleaned up acceptably and is much stronger than PLA or HIPS. The TPU also worked quite well despite being a complete pain to load. Based on this test I’d say that while the Ender is definitely most comfortable with PLA, if you set it up properly and protect it from cold draughts (I live in a 200-year-old house on a windy hill in Yorkshire) it can handle some much more demanding materials. In future posts we’ll look at how to get the best performance from our alternative 3D printer filaments, and what advantages each material offers. In the meantime, if you’ve been sticking to PLA feel free to experiment a little!

Leave a comment

You must be logged in to post a comment.