TL Smoothers – What Are They And Do They Work?

Obviously we think 3D printers are awesome, but there’s no doubt they can be temperamental beasts. Some printers work better than others out of the box, but most of them will benefit from some tweaking, tuning or upgrading to improve the quality of prints.

I’m always looking for ways to get better performance out of our Ender 3, and this week I found a very tempting offer on Amazon. A pack of TL smoothers promised, for just £12.99, to reduce noise and vibration and turn out better quality prints.

I know a bit about electronics, but I have to admit I had no idea what TL is and how you’d go about smoothing it. However, some investigation showed that a TL smoother is a fairly simple array of diodes, and the TL stands for Triangle Labs, who were the first people to sell them. The idea is that the diodes keep the voltage from the printer’s mainboard inside the range the stepper motors can use most efficiently, which should eliminate “chatter” – electronic noise that causes fluctuations in the motor speed. If that works it should be a big improvement, because chatter is one of the main causes of the print surface patterns called “salmon skin”. You almost certainly know what that looks like:

So How Do You Install Them?

Anyway, TL smoothers seem to come in two varieties – four-diode, or eight-diode. After watching some review videos it’s clear that the eight-diode ones give better results on a range of printers, but I didn’t find any info on what difference they make to an Ender 3. So I decided to buy a pack and find out.

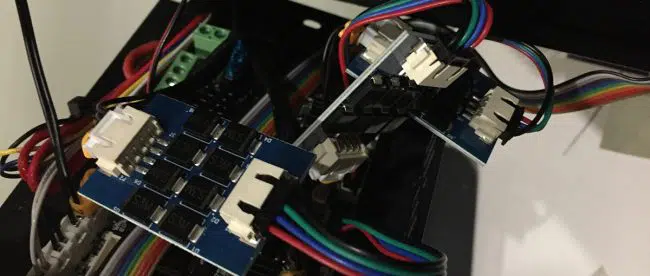

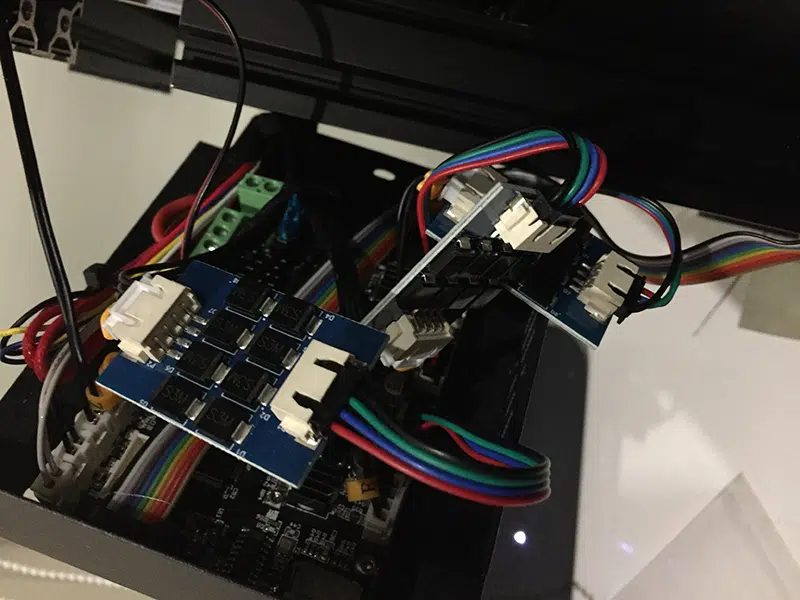

TL smoothers are a plug-in upgrade, but it took me a while to work out where to plug them in. Each small circuit board has a connector at each end, and comes with a short extension cable. My first plan was to plug them in between the Ender’s stepper motors and the main cable loom, but the connectors didn’t fit. In fact for a while I thought I’d bought smoothers that weren’t compatible with my printer.

In the end I opened up the electronics box and plugged the extension cables directly into the printer’s mainboard, added the smoothers and reconnected the main cable loom. Then I managed to stuff it all inside and screw the box shut again. I’m currently working on a tray that holds all three smoothers and will keep them clear of the cooling fan.

Does The Printer Still Work?

Anyway, I loaded up the TF card I keep my benchmarks and test files on, and started printing a 3D Benchy. One of these was the last thing I printed before installing the smoothers, so I just left all the settings the same to get a comparison.

Meanwhile I went back to work, just keeping an ear on the printer in case it started doing anything strange. It didn’t – and it was noticeably quieter than normal, too. It’s still a long way from silent, but the noises coming from the enclosure had lost a bit of their urgency. Would I buy TL smoothers just for the noise reduction? No; it’s not that significant. If they improve print quality, though, then quieter printing is a nice bonus.

And How Are The Prints?

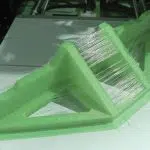

So that’s the big question – do they improve print quality? Well, I think they do. Looking at before and after pics, the diagonal salmon skin stripes that have appeared on the wheelhouse of every Benchy I’ve ever printed are gone. Not fainter; gone. On the down side there were a few noticeable layer change zits. That’s probably an issue I can tune out, though.

After 3D printing a fairly successful Benchy at 0.2mm layer thickness, I decided to change that to 0.12mm and try again. This is where things got a little puzzling, because it was awful. The salmon skin was still gone from the wheelhouse, but the entire hull was covered with closely-spaced diagonal lines. I suspect this might be some Z-axis wobble, and I’ll be doing some tests with the smoother removed from that motor – they’re more important on the X and Y axes, anyway. At standard quality, though, these little gadgets definitely boosted quality.

The Verdict

Adding TL smoothers to your 3D printer isn’t expensive or difficult. You do need to open up the box with all the scary-looking electronics in it – you can’t bodge things by plugging the smoothers directly into the steppers – but the hardest part of that is finding space for them in the box where they won’t block the airflow from the cooling fan. They do produce a bit of heat themselves, so fitting heatsinks to them isn’t the worst idea in the world either.

As for the results, I’ll be looking at ways to fix the issue with high-quality printing, but from the way the standard quality Benchy turned out I’d say this is a worthwhile upgrade. For half the price of a roll of filament, and five minutes of fidgeting with an Allen key and some connectors, you can eliminate one of the most common print quality problems. That sounds like a good deal to me.

Leave a comment

You must be logged in to post a comment.