Three dimensions, five-axes 3d printer?

IS A FIVE-AXIS 3D PRINTER POSSIBLE?

Compared to just about any other way of making things, 3D printing is amazingly versatile. It’s possible to make shapes that can’t really be made any other way. That’s not to say there aren’t limits, though. Some shapes are tricky even for a 3D printer. As for supports, that’s a word that’s guaranteed to make any printing enthusiast groan.

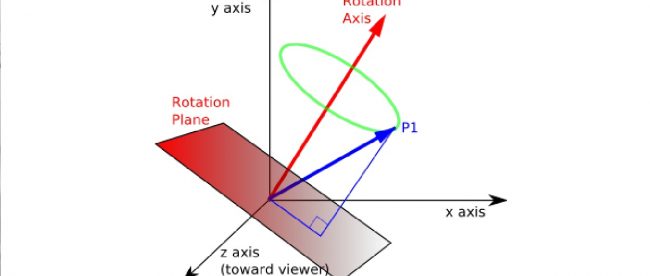

Most of the limits that exist are down to the way 3D printers – especially filament-fed ones – work. They print in three axes – two horizontal ones in each layer, and the stack of fused layers making the third – and that means there are some things you can’t really do easily. The biggest issue is that anything printed has to be printed on top of something – either the print bed or the next layer down – so overhangs require supports. That’s doable on the outside surface of an object, but on inside surfaces it can quickly become very complicated.

This looks like a problem you can’t solve. The limits are imposed by the three-axis design, but space is three-dimensional and printers already have an axis for each of these dimensions. It seems obvious there’s no way to add more axes, doesn’t it?

How does it work?

Well, actually there is. The extruder on a FDM printer moves in three axes – but you can make it rotate in them, too. If you do that a whole range of new possibilities open up. Want to create an overhang? Rotate the head vertically and print it from the top down. Add unsupported details to the side of a print by turning the extruder on its side. It suddenly becomes possible to do things very differently.

A printer with a rotatable extruder can operate in up to six axes, although it turns out that, in practice, you can do pretty much anything with five. The extra axes are added by starting with the existing ones the extruder moves in, and giving it the ability to rotate around them too.

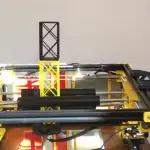

So can you get a five-axis 3D printer at home? Well, not affordably. Right now they’re on the market, but they’re a long way above the hobbyist level. The cheapest you’ll find is the British-made 5AxisMaker, which starts at around £5,000. You do get a lot for the money, of course. It has a 400x400x400mm build volume, and it’s not just a printer – it has a milling head too, so you can either build things up with filament or cut them down with a range of15,000rpm rotary tools. There are also versions available with 600x600x600mm and 1,000×1,000×1,000mm build volumes, with a higher price tag.

Want to spend more? That’s easy. Another British company, Q5D Technology, has just launched its CU500 printer. This can add embedded wiring to objects with an integral wire dispenser or even print circuitry from copper paste. It also has milling head options and each machine is custom-built; it costs about £200,000. Don’t despair, though. Yes, these are very expensive machines, and they also need custom software – normal slicers struggle to handle the extra axes. It won’t take long for prices to fall, though. Just as happened with standard 3D printers, expect to see five-axis 3D printer plans and kits for hardcore hobbyists appear in the next couple of years, followed by affordable consumer machines not long after.

Leave a comment

You must be logged in to post a comment.