Scientists Develop Flying 3D Printers

Obviously I think 3D printers are awesome. I think drones are awesome too. I remember when radio-controlled helicopters were expensive, complicated and prone to crashing, so the performance and reliability of modern drones is just amazing. 3D printers are amazing too, of course, so how much more incredible would it be if you could combine the two?

Well, you can combine the two. Lots of people print replacement or upgraded parts for their drones, and some even design their own drones, print out the airframe structure then add the motors and electronics. So 3D printing makes a big contribution to drones. Can drones make a contribution to 3D printing, though?

Well, it turns out that yes, they can. A team at Imperial College London and the University of Bath has developed new drones that can carry out building repairs in places human workers can’t safely reach – and they do it by 3D printing. The flying fabricators can work in areas that are difficult to access, for example around the top of high buildings. They could also be used in emergencies, where damage has made a structure unsafe. Instead of having to risk lives on emergency repairs the drones could patch it up enough to stabilise it and prevent collapse.

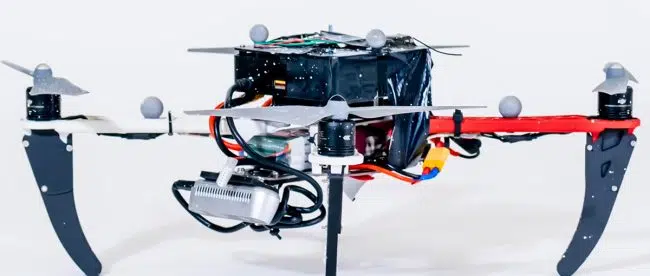

One of the most interesting things about the project is how the drones are controlled. They don’t need somebody on the ground with a controller, telling them what to do. They work as an autonomous network, with camera-equipped ScanDrones monitoring progress and directing the printer-equipped BuilDrones. The ScanDrones also feed information back to the ground, so a human can intervene if required – but, generally, they’re capable of assessing how the job is going and making the right decisions.

How Does It Work?

But how do you get a 3D printer onto a drone, anyway? There are a few challenges. One is weight; there’s a limit to how much a drone can carry. Then, obviously, it needs to print directly onto the building, with no bed or surrounding framework. That limits the printer technology that can be used.

Several different materials have been tested with the drones. One is a polyurethane foam compound, which is lightweight and suitable for emergency repairs. The others are “cementitious materials” – high quality structural cement. Each individual drone can’t carry a huge amount, but this system uses a swarm of drones, and between them they have enough capacity to repair cracks and patch up crumbling areas. To save material the drones print a lattice structure.

The 3D printer itself is a delta-style design, with the print head suspended from three arms that control its movements. While most delta printers have a platform they don’t actually need one; the drone can hover over the work area and print directly onto the surface. Each printer has custom software that monitors the movement of the drone itself – they’re never completely motionless in the hover – and compensate for that, so the printer isn’t thrown off track by every puff of wind. The team say they can achieve dimensional accuracy of less than 5mm, which is orders of magnitude less precise than a normal 3D printer but easily good enough for building work.

So far this is still a research project, but every stage of the process has been tested in the laboratory. The software works; the drones can work together to create large prints, under the supervision of the ScanDrones. The printers work too, at least indoors. If this technology takes off we could soon see swarms of flying 3D printers hovering around building sites.

This fascinating blog highlights some truly innovative uses of 3D printing and drones. Seeing how these technologies are coming together to solve complex problems, especially in challenging environments is amazing.

One aspect to consider is the maintenance of 3D printers

in diverse conditions. Using a 3D printer enclosure can be very beneficial to ensure optimal performance and longevity. It provides temperature regulation, noise reduction, and odor control, while also managing harmful emissions. I’ve been using such an enclosure myself and have found it incredibly effective in improving print quality and consistency.

Keep up the great work!