Italian Patients Saved By 3D Printing

CORONAVIRUS PATIENTS INSPIRE A LOCAL 3D PRINTING COMPANY

A few weeks ago we reported how a university hospital in China was using 3D printing to make custom face masks for medics treating coronavirus patients. There hasn’t been any more news on that, so whether it’s working or not we don’t know, but anyway the epidemic seems to be burning out in China.

Unfortunately it’s getting a lot worse everywhere else, but yet again 3D printing is being pressed into service to save lives. This time it’s happening in Italy, which is the hardest hit country outside China.

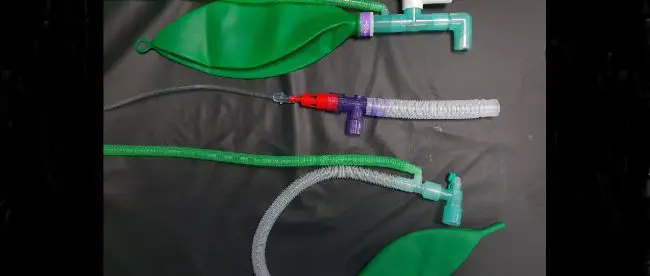

Last week a hospital in Brescia, in northern Italy, realised that it had a serious problem with spare parts. The hospital had 250 coronavirus patients and many of them needed breathing support from ventilators. Unfortunately the ventilators need specialist valves, which only last for about eight hours before they wear out, and with so many patients needing ventilators the hospital was quickly using up its supply of valves.

Supply chains

The obvious thing to do was contact the manufacturer of the ventilators and order valves from them – but they didn’t have any supplies, and couldn’t restart production quickly enough. A local journalist heard about this, but instead of writing a story she spoke to Isinnova, a local 3D-printing company, then put them in touch with the hospital.

A mechanical engineer from Isinnova immediately rushed to the hospital to examine a valve, then fired up his design software and got to work. A few hours later he was back at the hospital with a prototype, adapted for 3D printing. The hospital installed it in a ventilator and tested it on a patient – and it worked.

The engineer, Alessandro Romaioli, says the valve isn’t easy to print – it’s a complicated design and contains small holes and thin tubes less than a millimetre wide. Each one takes around an hour to produce, and Isinnova only has six printers. Once those were all working flat out on valves Romaioli, and the journalist, Nunzia Vallini, spoke to another printing company and struck a deal to get their printers on the job too. Inside two days they’d printed over 100 valves between them and another hospital had contacted them to ask for more.

The two companies are producing the valves at their own expense – they cost about 90p each to print – and working round the clock to keep the hospital supplied. Could they boost production by releasing the files for other people to print? Yes, but Isinnova chief executive Cristian Fracassi doesn’t want to go down that route. He says it’s important to make sure the valves don’t get contaminated as they’re printed (they’re going to be used by seriously ill people, after all) and this way the two companies can maintain quality control.

When you need it now…

Making these valves doesn’t involve any new technology. No new materials have been developed to produce them. This is just a perfect example of how 3D printing lets things get done at a speed that conventional manufacturing can’t hope to match. The original valve manufacturer couldn’t gear up production in time despite having made them before. A 3D printing company with no experience in the field was able to produce a new design that replicated the function of the original one, and manufacture a successful prototype, in around four hours. As soon as the prototype proved to work, it went straight into mass production.

How long would it have taken to get the valves using traditional manufacturing? A few days? A few weeks? How many people would have needlessly died while the hospital waited for them? Luckily, thanks to the capabilities of 3D printing, we’ll never know.

Leave a comment

You must be logged in to post a comment.