Review – Filament Welder

I’ve built up a pretty decent stock of 3D printer filament by now, including six different materials as well as the usual PLA in a variety of colours. Whenever I decide to print something I generally have the right material for the job on hand. I have another collection of filament too, though – spools of PLA, mostly black, that don’t have quite enough filament left on them that I’m comfortable using them for a big job. After all, who wants to start a 3D print job then have it fail 95% of the way through because the filament ran out and you didn’t notice in time to pause it and load a new spool?

Yes, I know; I could use those spools for small jobs, but sometimes I’m too rushed (or lazy) to spend time heating the nozzle, pulling out the old filament, changing spools and feeding in the new filament. So my collection of not-quite-empty spools is steadily growing, and taking up a fair amount of storage space.

Then, the other day, I saw a gadget on Amazon that promised to let me do something constructive with those odds and ends of filament. It’s a filament welder, which lets you connect two lengths of filament with a smooth join that will feed through the extruder and into the nozzle. Best of all, it’s only £9.99. At that price it looked worth a try, so we ordered one.

So What Is This Thing?

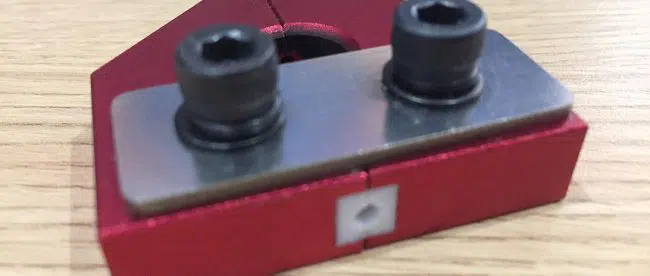

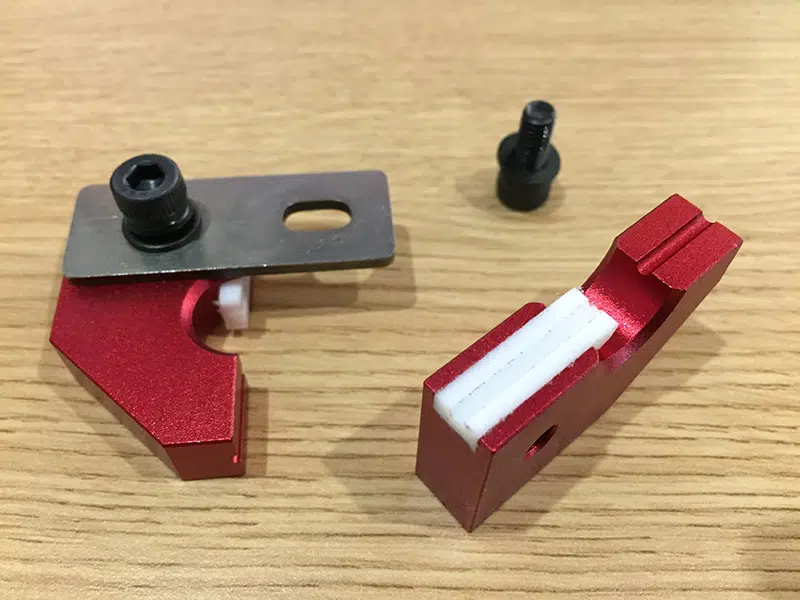

The filament welder is a simple enough device. It’s a two-piece aluminium body, held together with a steel strip and a couple of big screws. There’s a hole in the middle, a two-piece plastic insert in one end, and a 1.75mm filament tube running through the whole thing.

According to the instructions it’s also simple to use. You simply insert a piece of filament at each end, use a lighter to melt one of the ends, push them together then run them through the plastic insert a few times to smooth the join. Loosen one of the screws so you can separate the halves slightly to get the filament out, and that’s it – two pieces of 3D printer filament welded together into one new one.

Does It Work?

No.

Firstly, following the instructions too closely isn’t a great idea. You just want to melt the end of one piece of filament enough that the other will stick to it firmly. The instructions tell you to “burn it with fire for 5-7 seconds”. That’s great, except I quickly found that if you hold a lighter flame to the end of a piece of filament it will melt in less than two seconds. By four seconds it will almost certainly be on fire, and that’s a little hotter than you want.

Secondly, the joints you get aren’t all that smooth. I found that over half of them wouldn’t pass through the extruder, which obviously means no more material is reaching the print head and the print fails. I experimented with all sorts of things – rotating the still-hot joints inside the insert, scraping them with a knife, rubbing them down with sandpaper. It didn’t make much difference; this gadget simply doesn’t reliably make joints that will feed into your 3D printer. Sometimes they will, and sometimes they won’t; this benchy should have been printed out of a dozen lengths of filament, but even with sanded welds it only got to three before the extruder jammed.

I actually got on better simply holding a length of filament, melting the end, sticking another length to it then licking my thumb and forefinger and smoothing the join down. Reheating and smoothing a couple of times generally gives a pretty good weld; I stuck two short lengths to the end of a spool and printed this:

The Verdict

Overall, the filament welder is a good idea, but it just doesn’t work very well. I’ll keep playing with it, and if I find the magic technique I’ll let you know, but for now I can’t recommend this.

Leave a comment

You must be logged in to post a comment.