Infinite Z Axis 3D Printer Concept

A few months ago I talked about belt 3D printers, which can – in theory, anyway – print objects with an infinite Z axis. As long as you keep feeding it filament and whatever you’re printing doesn’t hit the wall a belt printer – for example, Creality’s new CR30 – will print objects of any length (or a continuous stream of smaller ones).

Belt printers aren’t perfect, though. They can’t use heated beds, because they print directly onto the flexible – usually rubber – belt. They also incline the print head at 45°, which can be a challenge for designing objects and also tends to require supports in unexpected places.

Is This The Solution?

I was searching through Thingiverse today and found a prototype printer that takes a completely different approach to the challenge of making very long objects. Apparently its designer, OB-3D, started out trying to design a 3D printer that could print masts, climbing the mast as it created it. Then he realised that someone had already done it. Most of us would have found another project at that point, but OB-3D is made of sterner stuff. Instead of giving up, he wondered if the concept could be adapted into an infinite-Z 3D printer where, instead of climbing a mast as it prints it, the printer remains on the desktop and extrudes a long print out the top.

Will It Work?

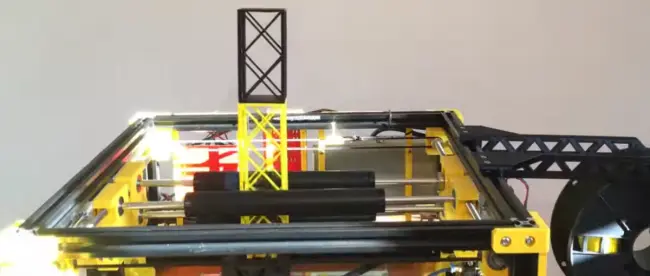

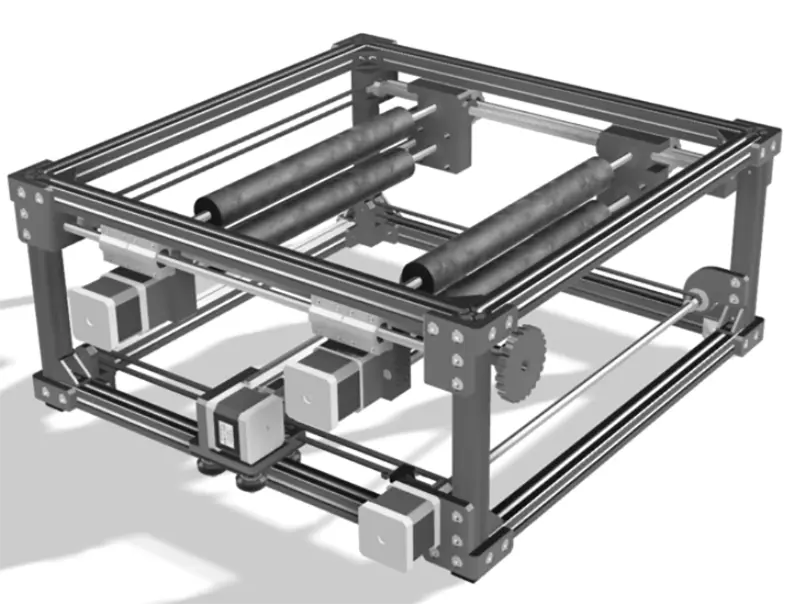

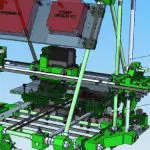

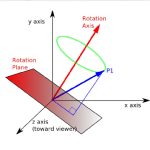

The concept is simple, but if you’re used to conventional 3D printers you’re probably wondering how the practicalities of an infinite Z axis work. OB-3D’s innovation is to turn the print head upside down and insert a removable “bed” on top of it. The bed is held by powered rollers, which lift it after each layer, and the next layer is printed onto the bottom. The printer creates a latticed support framework round the outside of the print; when the print gets tall enough the rollers grip that instead of the bed, and continue lifting it that way.

Because it needs to produce this large support, the printer obviously isn’t too economical with filament. Its creator also has some doubts about print quality, although from his photos and videos it looks like it’s doing pretty well for a prototype machine. The big problem I can see right now is gravity. Because it’s extruding the print out the top, once it gets tall enough it starts to look quite unstable – wobbly, to be blunt. There’s also going to be a point where the print is heavy enough that the rollers can’t physically lift it anymore, and I suspect print quality would be suffering badly quite a while before it gets there. Could that be solved by turning the thing 90° so it extrudes out the side, and the print can be supported? I don’t know, but it seems like that would be worth a try.

The good news is that, if you want, you can download CNC files for the parts and try building one yourself. Obviously the files can be edited if you have any ideas on how to make it work better. Will we see commercial printers using this principle? I’ll be interested to see that!

Leave a comment

You must be logged in to post a comment.