3D Printer Troubleshooting!

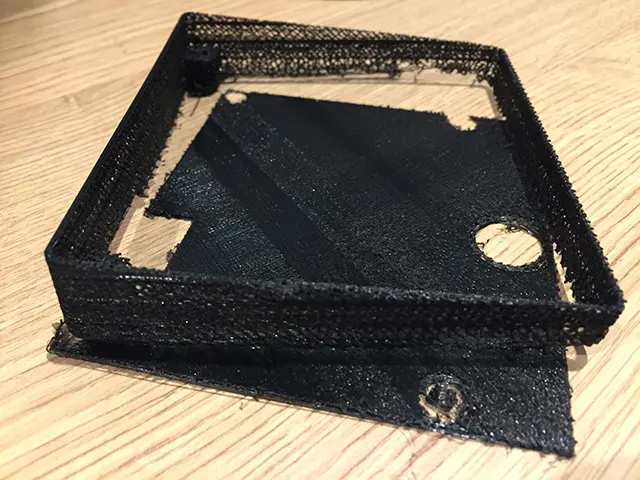

Since we got our Ender 3 it’s been producing 3D-printed objects pretty reliably – until late last week, when I tried to print a plastic enclosure for the back of the display unit. To my displeased surprise this looked like it had a terminal case of woodworm, and actually fell apart as I tried to prise it off the print bed. Clearly something had gone wrong, and I immediately set about trying to fix it by doing some 3D printer troubleshooting.

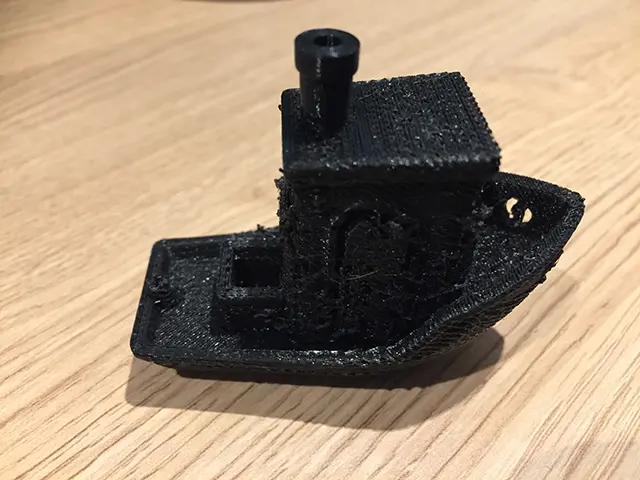

When 3D printers go wrong the first place to look is the bed. Specifically, is it level? A wonky bed can wreck print quality, so I went through the levelling routine again. And it didn’t work. The levelling test printed perfectly, but as soon as I went back to an actual object the same problems came back. This is clearly not a happy 3D Benchy…

With the bed thoroughly level I went through the problem logically. The first layer wasn’t always sticking reliably to the print bed. Subsequent layers were sometimes OK and sometimes barely there, riddled with tiny gaps and about as sturdy as a melted Kit Kat. I’d also noticed a sort of knocking sound from the printer. It was intermittent; sometimes I’d hear it every few seconds for a minute or two, and sometimes it would vanish for minutes at a time.

I checked over the printer and started another print, zipping up the enclosure to keep the noise down a little while I worked. The knocking sound kept reappearing though, and eventually I opened it all up to give it another check. After a few minutes of this I suddenly realised that I hadn’t heard the noise in a bit. Since I unzipped the enclosure, in fact. I left it open for a bit. No noise. Then I zipped it up. The noise came back. So I cancelled the print I was on and started a new one, then left the enclosure open and went back to work. When I checked a few hours later, I had a perfectly printed filament guide. Problem solved!

Er, no.

I had no idea why leaving the enclosure open might solve the problem, beyond some vague ideas about it getting too warm for PLA, but it certainly appeared to. However, when I ran another print it failed again. Badly. In fact it didn’t really print at all; when I came back to check on it there was just a raft on the bed, surrounded by a bird’s nest of stringy filament.

With that mess cleared away I ran yet another job, and finally figured out that the mysterious noise was coming from the extruder. It seems the extruder motor was running out of torque and slipping; the actual problem was a blocked nozzle.

Clearing a blocked nozzle isn’t a major job, so I heated it to 240° and ran the cleaning wire through it. Then I started printing another benchy. This worked perfectly until I was about ¾ of the way up the hull, and then the nozzle blocked again. Finally I did a cold pull to clear it, and now it seems to be fixed. Next time I’ll explain the cold pull technique, and have a look at the enclosure I’ve been using too.

Leave a comment

You must be logged in to post a comment.