The hardcore option – building your own 3D printer

BUILDING YOUR OWN PRINTER IS A CHALLENGE – BUT A WORTHWHILE ONE

We’ve looked at buying a 3D printer off the shelf, and then at putting one together from a kit. These are both great options, and for many people they’re going to be the most practical solution. That’s not true for everyone though. A lot of it depends on what you want your printer for. If you need to be able to print objects for work or a hobby, a ready-built one is probably the way ahead. But what if it’s 3D printing itself that interests you? Chances are it’s probably going to be more rewarding to build your own 3D printer.

Building a printer yourself has lots of advantages. For a start, it’s the cheapest way to do it. There are only a few specialised parts you’ll have to buy, and even they aren’t too pricy – for example most home-built printers use an Arduino board, and they cost about £15 ($25). Most of the other parts are fabricated from standard materials like plywood, glass or threaded steel rod; the real investment isn’t in materials, it’s in time.

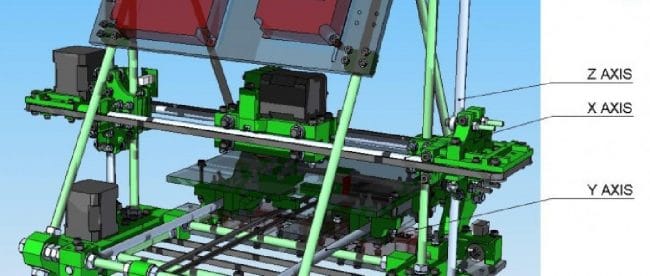

Designing a 3D printer from scratch is the ultimate project, but it needs a lot of specialist skills and can take a while. Most people who decide to home-build start with an existing design, usually a RepRap. You can choose to follow the design exactly, or customise it to suit your own needs – it depends how ambitious you are and how much confidence you have in your own skills. Of course one advantage of building your own is that you can start off by following the design, then experiment with it later – and if your custom part doesn’t work out you can just reinstall the standard one.

It’s not hard to find printer designs online, along with detailed build instructions. The RepRap Wiki has a full manual on building the latest Mendel design, for example. This includes full parts lists, templates and everything else you need to put a Mendel printer together. It also includes advice on how to source the specialised parts you’ll need. One feature of the RepRap line is that the printers are designed to manufacture many of their own parts. If you know someone who already has a RepRap you can get them to produce these parts for you, but if you don’t it can be tricky. One option is to have them made conventionally, but that can be expensive. Some companies are now offering sets of laser-cut parts that can replace the printed ones, and that’s a much more economical option.

Aiming to build your own 3D printer isn’t as simple as getting a kit. It’s definitely within reach of anyone with reasonably good DIY skills and a proper toolkit, but it does need a lot of precision and attention to detail. Parts have to be precisely sized, or the finished printer probably won’t work as you expect it to. You can also expect to have to do some tinkering and adjustment to get good results. On the other hand you’ll have a printer that you built yourself and you’re guaranteed to understand it inside and out.

Leave a comment

You must be logged in to post a comment.