Dollo 3D – the next RepRap?

THIS PRINTER SETS A NEW RECORD FOR MAKING ITS OWN PARTS

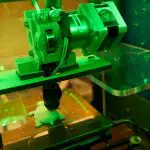

The Dollo 3D printer has a lot of 3D printing enthusiasts very excited. Their goal is a printer that can create replicas of itself. Self-replicating machines are an idea that go back to the mathematician John Von Neumann in the 1940s, and they’ve been involved in more than their fair share of apocalyptic science fiction, but for printers the benefits are obvious – a technology that can replicate itself is able to spread more quickly. The popular RepRap was designed to create as many of its own parts as possible and increases that capability with each generation, but now it looks as if this new crowdfunded design could leapfrog it.

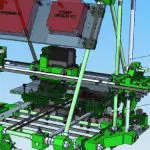

Intended to be fully open source, it was designed by a father and son team, Ben and Benjamin Engel. After building other open-source printers they decided it was possible to radically increase self-replicating abilities by replacing metal rods with printed parts, and the Dollo 3D is the result. It’s not just a highly printable printer, either; it has some unique and interesting features, plus the ability to be converted into different computer-controlled tools by changing the working head.

An increasing number of printers are following the space-efficient cube design, and the Dollo 3D continues the trend. Each of the cube’s sides is made up of interlocking plastic parts, and one of its most interesting features is that the size of the printer can be scaled by adding or removing blocks from the sides. The smallest you can build has a print volume of 140x140x90mm, which is quite respectable, but once you have that up and running you can print the parts needed to expand it. The standard print bed is oversized and mounted diagonally inside the frame, so when the device has been enlarged enough it can be turned to line up with the frame. This lets you at least double the print volume without having to replace the bed.

There’s a lot more to the Dollo than its scalability. It’s been designed without belts, eliminating the lashing effect that can cause inaccuracy in many other designs, so it’s capable of producing very neat, precise objects. It can also do more than just print. By replacing the print head with an optional tool module it can be quickly adapted into a computer-controlled milling machine or laser cutter. This is an incredible level of versatility, all in a basic device that costs under $500.

If the Kickstarter reaches its target the Dollo 3D printer should start being delivered around mid-September 2016. There are several options for getting your hands on one. The most basic is a kit containing all the electronics and a spool of ABS for printing the frame, as well as the files you’ll need. Then there’s a complete kit that includes the printed parts as well, or finally a fully assembled printer. The Engels say a working machine can be assembled from a kit in less than an hour; most of the parts simply slot together and there are only two dozen screws in the whole thing. It’s not just a very adaptable printer; it’s simple, too.

Leave a comment

You must be logged in to post a comment.