3D Belt Printers – What Are They For?

If you’re a regular reader of this blog you know pretty much what a Fused Deposition Modelling printer looks like by now. It has a print bed that the head moves over in the horizontal X and Y axes, then some kind of system to move the head in the vertical Z axis. The size of the bed, and the height of the Z axis system, set the boundaries of the volume you can print in, so every printer has its own limits on the size of object you can create with it.

But what if it doesn’t?

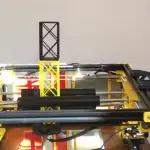

There’s a quite rare, and highly specialised, variety of FDM printer that breaks out of the usual mould and lets you make objects that, in theory at least, can be infinitely long in one axis. These are called belt printers, and if you’re familiar with the normal sort they seem pretty weird at first.

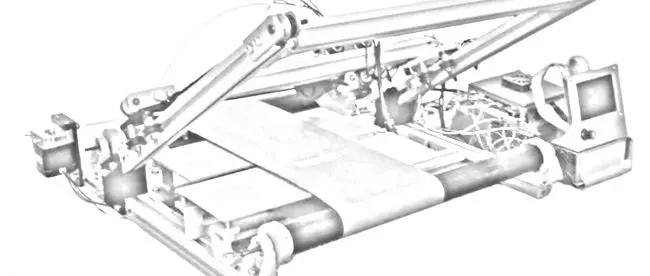

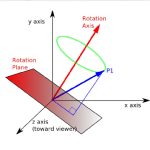

What sets a belt printer apart is that, instead of a conventional print bed, it has – you guessed it – a belt. The bed is replaced by a rubber conveyor belt powered by a pair of rollers at each end of the frame. This belt handles Z axis movement, and you can probably see an issue right there: The belt is moving horizontally, and the Z axis is vertical. How does it handle that?

On a 3D belt printer the extruder moves in a frame that handles the X and Y axes, and this frame is mounted to the printer at an angle of about 45°. Combine the extruder’s movements in the frame with the slow movement of the belt, and all three dimensions are covered – but, because the usual bed is replaced by a continuous belt, there’s no limit on the Z axis.

Well, sort of. While there’s no theoretical limit – as long as you keep it fed with filament the printer will go on adding to the Z axis – there are some practical ones. You’ll need to support the print once the end of it starts to move past the roller, usually by setting up a table at the same height as the belt. At some point the material will also reach its limits, and you risk having the object break under its own weight when you pick it up. Even taking that into account, though, a belt printer throws traditional Z axis limits out the window.

Yes, but what’s the point?

A 3D Belt printer has a couple of advantages over its conventional relatives. The main one is obvious: If you want to print an object that’s very long in one axis, this is the way to do it. As long as it fits inside the printer’s X and Y window the Z axis is only really limited by the material you’re using and the size of your workshop.

Here’s another one. What if you want to print a lot of objects at once? With a conventional printer you always end up playing Chinese puzzles trying to fit as many as possible onto the bed. With a belt printer, the moving belt means it has an infinite amount of bed space; you just load the model and tell it to keep printing copies. Then put a bin under the end of the belt, sit back and watch it fill up with completed prints.

Should I get a 3D belt printer?

Honestly, 3D belt printers aren’t for everyone. They’re more expensive, for a start (although Creality and iFactory both have sub-£1,000 models in the pipeline). If you like printing on a heated bed – or any bed that isn’t made of flexible rubber – you’re out of luck. You’ll need to learn a new approach to supports, too, because belt printers often need supports where normal ones don’t (although that works both ways – sometimes they don’t need supports where normal ones do).

If you make a lot of copies of an object, though, or you have an urgent need to print a 17-foot-long girder, a belt printer might be just what you’re looking for. With more affordable models starting to appear we expect them to become a lot more popular this year.

Leave a comment

You must be logged in to post a comment.