3D Printer Nozzles – What Difference Does Size Make?

So far, everything I’ve 3D printed has been squeezed out through a standard 0.4mm nozzle. That’s not a big deal; 0.4mm is a perfectly good size for a 3D printer nozzle, and in general it’s worked pretty well. There are other sizes though, and this week I decided it was time to try some out. After all I’d ordered a pack of assorted nozzles, and even made a little rack for them, so why not see how they printed?

Something Different

Obviously for any kind of 3D printer performance test I’m going to end up printing a couple of Benchies, and of course that’s exactly what I did, but I decided to try something a little different as well. While poking around on Thingiverse I came across an interesting-looking iris box. This is a one-piece 3D print that needs to be done quite precisely, so its internal mechanism all works, and I thought it would be a nice challenge. So I printed three of them, using different-sized nozzles. Here’s how it went.

One To Compare

I started off by printing a box with the usual 0.4mm nozzle, just so I had some basis for comparison. To my total lack of surprise it came off the printer in one solid piece, which reminds me; I should probably explain what an iris box actually is. Open, it looks like a small round tub – but if you twist the base, four curved leaves emerge from the top edge and close it off. Like this:

Well, at first it didn’t do this because, as I said, it was one solid piece. However I followed its creator’s instructions on how to loosen it up, and it worked! The first few times I opened and closed it were slightly gritty, but it’s a lot smoother now. So, clearly, this is a design that works with a standard 0.4mm nozzle. That was good to know before I went any further.

By the way, it took just under nine hours to print.

Going Large

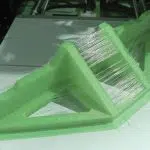

With the basic concept proved, I swapped out the 3D printer nozzle for a 0.8mm one and printed a second box. This one only took five hours to print and came out looking OK, but there were some signs of lower print quality – the floor of the box had very obvious lines, for example. More to the point, no matter how much I pried and levered at the bits I couldn’t get it to work. I finally gave up after stabbing myself in the hand. I think the line width was just too imprecise to work with the somewhat complicated innards of this model.

While I had the 0.8mm nozzle installed I also ran off a quick Benchy – and I have to say, it was quick. It printed in less than an hour and a half, compared to about two hours with the usual 0.4mm nozzle. As for the quality it was surprisingly good. In fact the hull and the sides of the wheelhouse were excellent – one of the best of the dozens of Benchies I’ve printed. Fine details were less good, though. The nameplate on the stern was a blurred mess, and the hawse holes up front were ragged.

Is Small Beautiful?

Next, I switched to the 0.2mm nozzle and tried again. This box came out looking great, with very crisp detailing, and it was easy to free up all the parts. However, it didn’t actually work all that well. In fact only three of the four leaves extended the first time I tried it, and by the end of a day that was down to one. To be fair, though, I can’t say for sure that was anything to do with the nozzle size. The leaves seem to have slipped out of their correct positions and got jammed, which could just be bad luck.

Predictably, with the smaller nozzle everything took longer to print. The very nice Benchy I printed took just over three hours, while the box itself needed an eye-watering 15 hours 36 minutes.

The Verdict

Overall, the results here were pretty much what I expected. The 0.8mm nozzle is less than ideal for precision, so if you’re 3D printing something with a lot of fine detail you probably don’t want to be using this. On the other hand it’s much faster than a standard nozzle, and it also has fewer lines (and so fewer potential points of failure). If you need a prototype in a hurry, or you want to print something as strong as possible, a larger nozzle like this definitely has a place.

On the other hand, the 0.2mm nozzle is s-l-o-w. It takes at least 50% longer to print anything than a 0.4mm, and sometimes much more. The payoff is in the print quality, particularly on those small details. This is the perfect 3D printer nozzle for high-quality decorative prints.

One last thing – make sure the line width setting in your slicer matches the nozzle you have installed. I accidentally printed one Benchy with 0.2mm line width but a 0.4mm nozzle. It actually looked pretty good, but it’s noticeably lighter than all my other Benchies and my guess is that if this was a load-bearing component it would fail.

Leave a comment

You must be logged in to post a comment.