PolyJet Printers – The Next Big Thing?

A few years ago, pretty much every affordable 3D printer used Fused Deposition Modelling to create objects by melting plastic filaments. In the last couple of years we’ve seen Stereolithography machines, which build up models by selectively hardening layers of resin in a curing tank, drop down into the hobbyist price bracket. There’s another printing technology which combines elements of both of these, though – PolyJet printing. Right now this is only available in expensive professional machines, but we think it’s likely to appear in consumer models over the next year or two. In fact we hope it is, because it has some really exciting possibilities!

So What Are They?

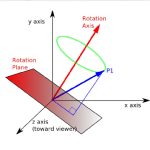

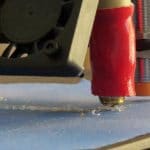

PolyJet resembles FDM printing by having a print head that adds material to the project, layer by layer. The difference is that instead of feeding a filament into a heated nozzle, it sprays a thin layer of liquid polymer on top of the previous layer. An ultraviolet light or laser then cures the polymer, hardening it – just like a SLA printer. You can think of it as an inkjet printer that works in 3D and uses plastic ink; the basic head design is very similar.

Obviously inkjet printers are pretty much obsolete now; they’re slow, noisy and the ink cartridges cost a fortune. With a good colour laser costing £150 or less, there’s no real reason to get one. The thing is, affordable colour lasers are fairly recent, and not that long ago inkjets had one really big advantage – they were the only way to print in colour without spending a fortune.

Because PolyJet printers use the same basic print head design as inkjets, they can be loaded with multiple print materials at the same time – and combine them as they print. That gives them much more advanced colour-printing capabilities than other printers. SLA is pretty much limited to printing in a single colour, and with most FDM machines your only option is to stop the print job, switch to a different colour of filament then resume. A PolyJet can use different colours in the same layer, though, so true colour printing is completely achievable.

It can also use different types of material in the same layer. If you want a model to have more rigid parts and more flexible ones, you can do that. You can also print supports with a soluble material, and use a solvent bath to dissolve them away once the job is complete. It’s possible to print quite complex structures, with a mix of transparent and opaque parts.

In terms of print quality, PolyJet printers can print very fine layers, so the resolution of printed parts is excellent; it’s extremely good at reproducing fine details and smooth curves. On the other hand, prints tend not to be as strong as FDM ones. PolyJet polymers don’t have the rigidity of ABS or even PLA, so it’s more suitable for decorative items or prototypes than mechanical parts.

The Verdict

Right now, PolyJet printers are expensive – they start at around £5,000 and go up to £60,000 or more. We don’t think it’s going to stay that way, though. All the technology they use already exists in affordable forms; it’s just a matter of someone combining it to make an affordable PolyJet. Hopefully that happens soon, because they’re a very versatile option.

Leave a comment

You must be logged in to post a comment.