3D Printer Tech And Classic Cars

3D PRINTING TO THE RESCUE

Back in January we looked at how a 3D printer can rescue old toys or games that need a replacement part. It was an amusing story about what you can do with an entry-level 3D printer, but it turns out it barely scratches the surface of the real possibilities. Using the sort of printers that are now becoming common in industry it isn’t just old toys that can be resurrected; it’s just about anything.

If you’ve ever owned a classic car you’ll know all about tracking down increasingly scarce spare parts. As original stocks run down, owners find themselves searching ebay for parts or even rummaging through scrapyards. Sometimes reproduction parts are available, but thanks to the cost of making tooling for small production runs these can get expensive in a hurry.

On the other hand, 3D printing is perfect for small production runs. Once you have the file for a part, it’s as cheap to print one as a million – and the growing availability of 3D scanners makes getting the files simpler than ever.

Bringin’ It Back

Several car companies have already used 3D printing and classic cars. When BMW bought Elvis Presley’s 507 Roadster from an Alabama farmer in 2014, they used a lot of printed parts to restore it to its former glory. Jaguar, Bentley and Bugatti have all used printed parts to rebuild – or even completely recreate – classic designs.

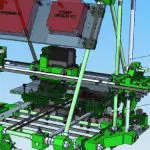

Of course it’s easy for a car company to make parts for its own designs. Even if the production line was shut down years ago the chances are they still have all the original drawings, and turning those into a 3D model isn’t hard. They also have access to high-end printers that can make metal parts. Porsche Classic now has an entire 3D-printing department that makes both plastic and metal parts for old Porsches, tested to the same specifications as the original parts.

Be Your Own Parts Supply

What about individual owners, though? If you don’t happen to have access to Porsche’s Formula 1 workshop and its millions of pounds worth of laser-sintering equipment, can you still use 3D printing to keep your classic on the road? Yes, you can. You might not be able to print a new transmission case or exhaust manifold, but a lot of smaller parts can still be recreated.

Firstly, you can use a 3D printing service; just give them the 3D model and they’ll print the part for you. It’s your only option if you want functional metal parts, but you’ll also get a wide choice of materials and finishes for plastic parts too.

There are also a lot of parts that can be printed on any home printer. It can be hard to match the colour of originals with a standard printer (unless it’s black) but small trim parts, switches, buttons and so on are often possible. You can also make plastic parts that might be essential but aren’t conspicuous. Cable clips, door lining fasteners and window mechanism parts can all be produced, either from models downloaded online or by measuring an old part and doing some design work at home.

Restoring Elvis’s BMW or printing a custom grille for a 1969 Camaro is an expensive job however you do it, while using a door clip as a template to print half a dozen ABS ones at home is pretty cheap. Of course the price is going to keep falling as printers themselves become more affordable, and it won’t be that long until classic cars going off the road because of a shortage of parts is, unlike the cars, a thing of the past. It won’t be too long before 3D printing and classic cars become the norm.

Leave a comment

You must be logged in to post a comment.