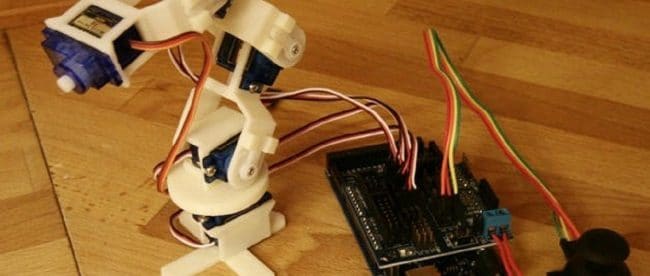

MIT breakthrough brings 3D-printed robots closer

NEW TECHNOLOGY COULD BRING US A 3D PRINTED ROBOT

One limitation of 3D printers is that while they can make components there are restrictions on their ability to create complete, ready to go systems. The idea of a printer that could create robots without human intervention is still in the realms of science fiction. It’s just moved a little bit closer to reality though, because researchers at MIT have made a major step forward in printing diverse materials. Their latest innovation is able to print both solids and liquids at the same time, so hydraulic actuators can now be created in a fully functional state.

MIT already have some experience at multi-material printing. Their MultiFab design, which went into action last August, is capable of using up to ten different materials at once – and can even integrate other components, such as batteries or LEDs. MultiFab was also aimed at testing robot-making techniques, and the new system takes it a step further.

What they’ve done this time is an advance in materials rather than hardware. They’re using a standard stereolithography printer, which uses ultraviolet light to harden droplets of liquid resin. What they’ve done is set it up to print multiple materials, and added liquid – usually hydraulic fluid, but lubricants can also be used – as well as the usual resin. When resin is printed the UV lights will immediately harden it into solid plastic, but the liquid materials won’t be affected. As long as the design keeps the liquid inside sealed containers it will stay where the printer puts it, so devices like hydraulic actuators and pre-lubricated gearboxes can be created.

This is obviously a huge boost for robotics. We’re still not at the stage where a robot can be printed and walk out of the printer under its own power, but MIT’s work has now brought a 3D printed robot a big step closer. The researchers believe it will be possible one day, and probably not too far in the future. With the capability to print an object from multiple materials, including liquids, and to seamlessly add other components during the print cycle, most of the technology is now in place. Future printers should be able to build a robot’s body, complete with integrated wiring and motors, then insert – or even print – its control circuitry and load it with the necessary programming.

Being able to print a fully operational 3D printed robot opens up a lot of possibilities. Right now, if your drain gets blocked and you can’t reach it with a bent coat hanger you call a plumber. In the future perhaps you’ll be able to print a small robot, drop it down the plug hole and let it find and clear the obstruction. Then it could either climb back out the drain, to be cleaned up and stored for the next emergency, or disassemble itself into parts small enough to be washed away.

Simply printing droplets of liquid isn’t hard; after all every inkjet printer can do it – but the ability to combine liquids with solid printed parts is a big advance. MIT are making a lot of progress on printed robotics and we can expect exciting things from them over the next few years.

Leave a comment

You must be logged in to post a comment.