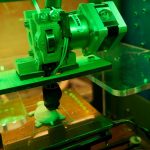

How to feed your 3D printer

THE CHOICE OF PRINTABLE MATERIALS IS GROWING ALL THE TIME

When you start looking for a 3D printer it’s easy to get too caught up in the specifications of the machine itself – the size of object it can create, its resolution and print speed, for example. All of these are important, but probably the most important thing is one that a lot of buyers don’t consider – what it can print with. This is a much bigger deal for 3D printers than it is with an inkjet or laser. After all, anything that puts colour on the paper will do for most applications. That’s not good enough when you add an extra dimension.

With a 3D printer you’re creating an actual object, and what it’s made of is absolutely vital. There are printers that can print with chocolate, in very high resolution – but would you want to make your new phone case out of it? You need to work out what sort of projects you want to do, decide on the right materials for them then find a printer that can use them. That’s getting simpler, because there’s a growing range of materials and many printers can use several of them. Here are the main printing materials on the market so far:

- ABS. Acrylonitrile butadiene styrene, despite the unpronounceable name, is a very common plastic. It’s thermoplastic, meaning it melts when heated into a form that can be extruded by a print head. ABS is strong, flexible and cheap, making it one of the most versatile printing materials. If you want to make durable cases it’s ideal, for example. Its low cost means it’s also ideal for experimenting with.

- PLA. Polylactic acid is another popular thermoplastic. It’s slightly more expensive than ABS and it’s also weaker and more brittle, so it’s less suitable for protective cases and anything that might be dropped. It’s biodegradable though, which helps reduce plastic waste. PLA is sustainably sourced from plant materials. One big advantage is that transparent PLA is available.

- Nylon. This is one of the most widely used plastics, and many 3D printers can use it. Nylon is very strong, but more than twice the price of ABS or PLA. It’s also far more durable than either of them though, so if your printer can use it consider using ABS to make prototypes, then nylon for the final object.

- Wood polymer composite. If you want the texture and appearance of natural wood, you can get close to it with a product like Laywood. These are a mix of powdered wood and a thermoplastic, usually PLA; they print just like plastic, but with a wood content of around 40% they have a distinctive feel. Wood composite scan be stained like real wood – but check the product you use won’t disintegrate the plastic! It’s best to make a small test object first.

- Metal composites. Like wood, metal can be powdered and mixed with plastic to create a printable filament. These will create objects that look like metal, but they aren’t as strong.

New materials are appearing all the time, and there are now specialised printers that can use paper or ceramics as well as the more common plastics. One big advantage of the technology is that by fitting new extruders it’s often possible to upgrade an existing printer to use new materials – especially with an open source design like a RepRap. Even if the perfect material for your project isn’t available now, it could be very soon.

Leave a comment

You must be logged in to post a comment.