Building a 3D printer kit

YOU CAN SAVE A LOT WITH A KIT, AND STILL GET STARTED EASILY

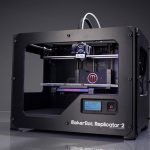

We’ve looked at buying a 3D printer, and the advantages it offers – especially if you just want to get printing as quickly as possible. This convenience does come at a price premium though, so for those who don’t really see themselves as hobbyists and want a commercial printer, but prefer to save on the cost, there’s also the option of building one from a kit.

Building a 3D printer kit has several advantages. One is the price, obviously; depending on the model you choose you can save anything from £50 to several hundred on the cost of an assembled machine. You’ll also have a solid understanding of exactly how your printer works, which can be very useful if you ever need to do any troubleshooting – and it can help you avoid mistakes in designing print projects, too. Sometimes you’ll be working on a design and you’ll realise that it just isn’t going to work with your printer, so you can find another solution without wasting too much time on it.

Obviously the cheapest way of getting a 3D printer is to build one yourself, either from a design or if you’re really ambitious from scratch. A kit is a lot simpler though, and you have the reassurance of knowing that all the parts should be compatible. That’s not always the case, because some kits aren’t complete – they contain the basic structure but you need to add your own control board or motors, for example – but it usually is. If you go for a one-box kit you know that every component has been selected to work with the others, and that putting them all together the right way will create a working printer.

You’ve probably got the idea that there are different kinds of kits. Most of them should contain everything you need, but the amount of assembly can vary. Sometimes you’ll get a set of subassemblies that just need to be put together – this might take as little as an hour or two. With others you’ll get bags of components, and assembly can involve quite a bit of work with a soldering iron. What you go for depends on how much you want to save, how much work you’re able and willing to put in, and of course what the options are for the printers you’re interested in.

Then there are partial kits. This is especially popular for the RepRap, which was designed to be able to print as many of its own parts as possible. Most builders get a RepRap owner to print out those bits then buy the other components, but there’s an increasing variety of kits that contain all the non-printable parts. There are other kits that contain the frame or cabinet, drive mechanism and other components, but let you choose your own electronics, motors and extruder. These are great if you have special requirements – an non-standard extruder to handle specialist materials, for example. Finally you can even get a monthly magazine that comes with some parts in the bag with each issue, so you can spend most of a year looking at an incomplete (and increasingly obsolete) printer, then five minutes a month screwing the latest bits on. This is an expensive option too – you could buy a superior ready-built printer for less.

If building a 3D printer kit appeals to you there are plenty options out there. It’s slightly less convenient than a ready-to-go one, but a good bit cheaper, and still a quicker way to get up and running than doing it from scratch. In future blogs we’ll look at some of the best kits on the market.

Leave a comment

You must be logged in to post a comment.